For batteries to fit into narrow and crooked spaces and to store more energy for e.g. electric mobility, flexibly adaptable cells are required. So far, however, lithium-ion battery cells have been produced in standardized formats and rigid systems. Scientists of Karlsruhe Institute of Technology (KIT), together with partners in science, are now developing an agile production system for flexible battery cell production in terms of format, material, and quantity. The second project phase - AgiloBat2 - started in January and is funded by the Federal Ministry of Education and Research (BMBF) with a total of EUR 14.5 million.

Worldwide, battery research is gaining relevance. The question of how batteries can be adapted to the installation space available, however, has been neglected so far. Today, it is common practice to have standardized battery formats and to adapt the installation space. Another challenge: Lithium-ion cells among others consist of rare elements, such as cobalt and nickel, whose costs are fluctuating strongly and whose supply situation becomes increasingly critical.

"Intelligent and sustainable battery cell production is of decisive importance to future mobility, but also to electronics used today, such as smartphones," says the President of KIT, Professor Holger Hanselka. "Within the AgiloBat2 research project, KIT researchers and our partners from science work on enabling agile production in Germany. With an agile production system, battery cells can be adapted individually to the respective requirements - and this will open up many new opportunities."

About a year ago, AgiloBat1 started as a mere development and concept phase of the Innovation Campus "Future Mobility" (ICM) funded by the Baden-Württemberg Ministry for Science, Research, and the Arts. The BMBF-funded implementation phase, AgiloBat2, started in January 2021 as part of the Intelligent Battery Cell Production (InZePro) competence cluster. All findings obtained in this implementation phase will be incorporated in the development project.

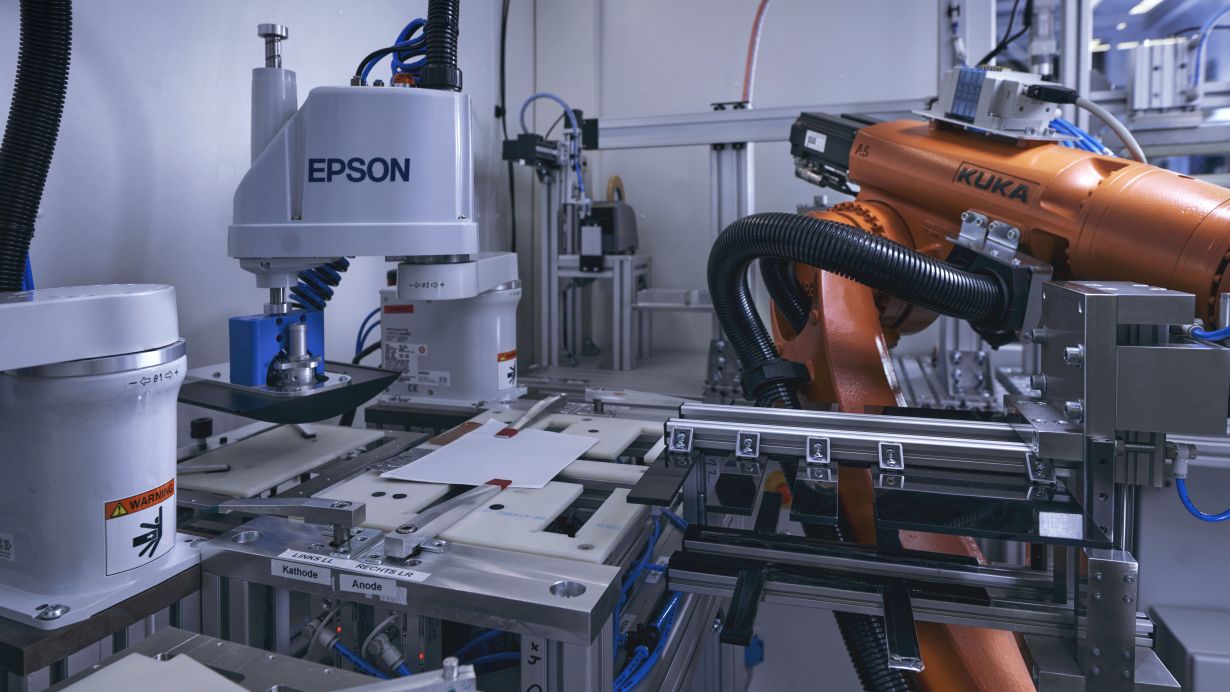

assembly, is a prototype production cell for

the AgiloBat production system. (Figure: wbk)

Agile Production System Will Be Set up at the Karlsruhe Research Factory

First, the team of researchers will design the adaptable production plant. Adaptability will be achieved by the setup of a digital twin that realistically models both the overall process and individual processes. In this way, the system can be configured quickly based on the characteristics chosen. In parallel, the production system proper is constructed. "We will set up an agile production system at the Karlsruhe Research Factory. It will differ considerably from all production systems used for battery cell production so far," says the initiator and head of the projects AgiloBat1 and AgiloBat2, Professor Jürgen Fleischer, Head of KIT's Institute of Production Science (wbk). "Contrary to currently established rigid production lines, our system will be scalable. This will enable economically efficient production of small to medium quantities of various materials and formats." Standardized robot cells will accommodate the production modules. There, the steps to produce various formats will take place. Parallel to production, quality assurance will prevent rejects.

Testing of the modular systems will start in 2022. Both projects will be completed in late 2023 by the final evaluation of the agile production system and the corresponding cell design.

Participating Institutes and Integration in Battery Competence Clusters

The AgiloBat2 research project is carried out by the wbk Institute of Production Science in cooperation with the KIT's Institute for Applied Materials - Energy Storage Systems (IAM-ESS), Institute for Mechanical Process Engineering and Mechanics (MVM), Institute of Thermal Process Engineering (TVT), the Thin Film Technologies (TFT) Group, and the Fraunhofer Institute for Chemical Technology (ICT).

The Baden-Württemberg State Ministry for Science, Research, and the Arts funds the AgiloBat1 project with EUR 4.5 million. AgiloBat2 is part of the competence cluster Intelligent Battery Cell Production (InZePro). Work is linked to the competence cluster Analytics / Quality Assurance (AQua). (mkl)