A new piece of equipment being trialled at the University of South Australia (UniSA) in 2025 could provide a lifeline for the nation's decaying infrastructure.

UniSA structural engineer Professor Yan Zhuge hopes to improve the accuracy of the Hopkinson bar, a standard apparatus used in civil engineering to test how different building materials respond to extreme mechanical stress.

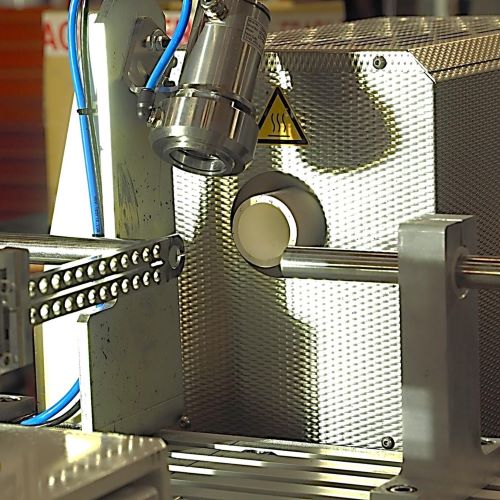

Prof Zhuge will take delivery of a $720,000 new-generation biaxial Hopkinson bar that uses electromagnetics to apply pressure in two directions, investigating how well the materials stand up to a high-impact force, including bombings, gas explosions, lightning strikes, typhoons, large hailstones, and tornadoes.

The equipment is partly funded by a $420,000 ARC Linkage Infrastructure Equipment Facilities (LIEF) grant, and supplemented with $300,000 cash from eight Australian universities, coming on top of a $402,221 ARC Discovery Project grant awarded to Prof Zhuge in the same month for a separate project.

"Australia urgently needs more effective design methods to ensure its ageing buildings, bridges and roads can withstand a projected increase in natural disasters by 2050 due to climate change," Prof Zhuge says.

"It is essential that we create sturdy structures and systems to protect against a whole range of events, including human-made disasters. The existing testing methods for construction materials are not only time consuming but often inaccurate."

The Hopkinson bar is a mechanical device invented in 1914 by British electrical engineer Bertram Hopkinson, originally used to measure the pressures created by small explosions and projectile impacts. In 1949, Herbert Kolsky improved the technique by using two bars to measure the stress and strain that materials can withstand.

In the intervening years, the Hopkinson bar has been modified to allow for tensile, compression and torsion testing.

Prof Zhuge says the existing bar is not advanced enough to test new materials that have different impact energies, hence the need for improvements.

A separate ARC Discovery grant awarded to Prof Zhuge will investigate 3D printing of reinforced concrete.

3D printing is now common in digital construction, but it is currently restricted to printing concrete, not the reinforced material, so cannot be applied in a real-world setting.

"This is the first research project in the world to see if it's possible to simultaneously print fibro reinforced polymer along with concrete," Prof Zhuge says.

The project will also investigate a sustainable 3D printing alternative to Portland cement - an alkali-activated slag binder that hardens quickly and has significantly lower CO2 emissions.

Prof Zhuge says the research findings will shape the next generation of digital construction, using robotics to replace manual labour.

The three-year project is due to start in July 2025.