Abstract

A research team in the Department of Energy and Chemical Engineering at UNIST has unveiled an innovative technology for converting waste plastics into carbon nanotubes (CNTs), a high-value material that plays a critical role in achieving carbon neutrality and promoting a circular economy.

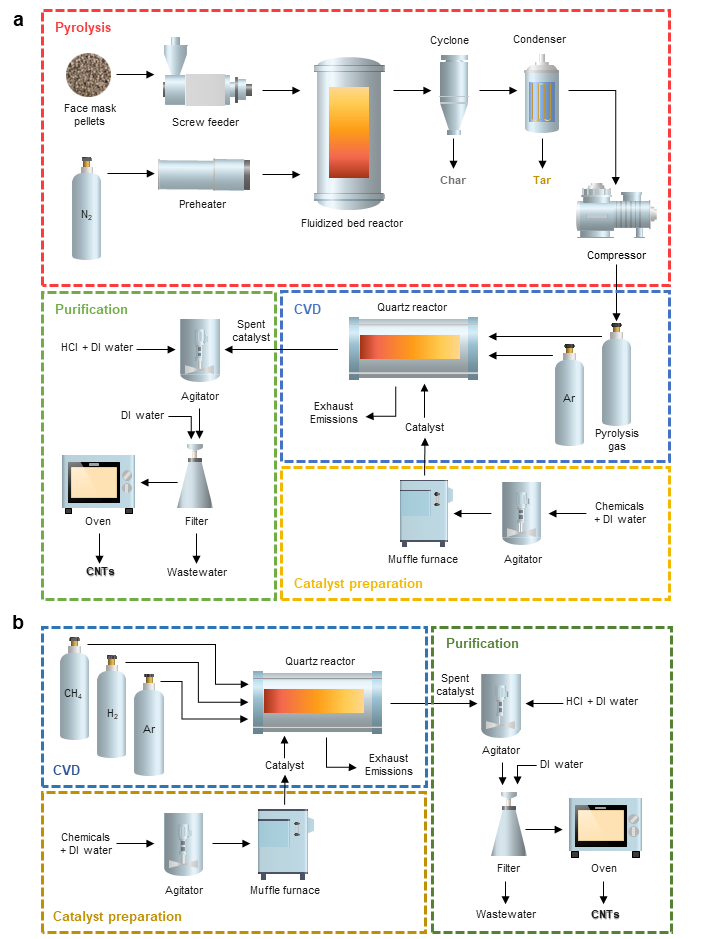

Led by Professor Kwangjin An and Professor Hankwon Lim in the School of Energy and Chemical Engineering and the Graduate School of Carbon Neutrality at UNIST, the joint research team developed a method to produce carbon nanotubes using mixed gases generated from waste mask substances. During the pyrolysis of waste plastics, these materials are transformed into hydrocarbon gases, including methane, ethylene, and propylene. The researchers harness these gases, subjecting them to high-temperature treatment to create CNTs.

Figure 1. Process flow diagram of the (a) upcycling and (b) conventional process for CNTs production.

The carbon nanotubes generated through this upcycling process are eco-friendly, producing lower carbon dioxide emissions compared to traditional methane and hydrogen-based methods. Notably, this approach eliminates the need for a waste separation process, streamlining the procedure.

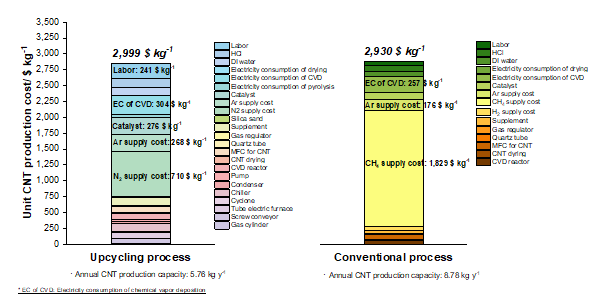

By utilizing the gases produced from the thermal decomposition of mask waste, the research team demonstrated that carbon nanotubes can be mass-produced at a low cost. Remarkably, the upcycling process operates at costs comparable to existing methods, despite the complexity of the system.

Figure 2. Unit CNTs production cost of upcycling process and conventional process.

In addition, the research team has outlined a carbon neutrality strategy through scenario analyses utilizing renewable energy sources. This study marks the first economic and environmental evaluation of carbon nanotube production via waste plastic upcycling, revealing a promising avenue for transforming plastic waste into high-value materials.

First authors Kim Hee-hyang and Nam Eon-woo stated, "The process can achieve low production costs if scaled up and if supply and demand for electricity are managed effectively using renewable energy. This would result in a significant reduction in carbon dioxide emissions."

Professors Hankwon Lim and Kwanjin An emphasized, "An increase in carbon nanotube supply due to advancements in pyrolysis technology will also enhance energy security."

This research was supported by the Carbon Neutrality Demonstration and Research Center of UNIST, the Agency for Defense Development, and the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (MSIT) and the Ministry of Trade, Industry and Energy (MOTIE), along with contributions from JEIO Co.,Ltd. The findings were published online in the international journal, Chemical Engineering Journal on June 28, 2024.

Journal Reference

Heehyang Kim, Eonu Nam, Kwangjin An, and Hankwon Lim, "Laboratory-scale plastic upcycling and green growth: Evaluating the upcycling of plastic waste into carbon nanotubes from economic and environmental aspects," Chem. Eng. J., (2024).