Dr Ben Allardyce and PhD candidate Mr Martin Zaki from Deakin's Institute for Frontier Materials' (IFM) have delivered a world first in next generation materials research.

Silkworm silk is a protein-based fibre with mechanical properties rivalling petroleum-derived synthetic fibres yet spun using a fraction of the energy. Despite decades of research, aspects of natural silkworm spinning remain a mystery.

Published in the prestigious Advanced Materials journal, the IFM discovery takes researchers one step closer to solving this mystery by wet spinning a new class of silk that produces fibres that outperform natural silk.

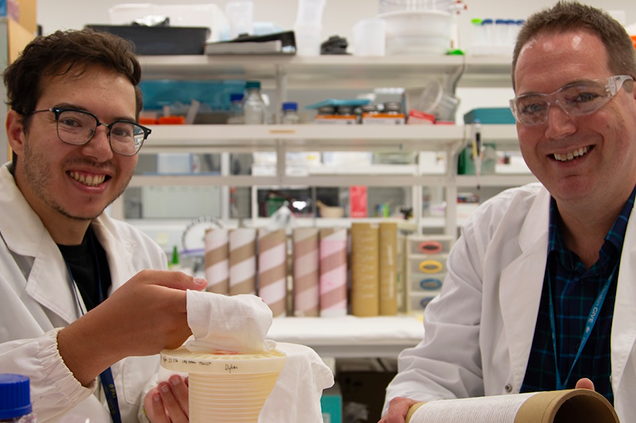

PhD candidate Mr Martin Zaki and Dr Ben Allardyce display the undegummed silk fibres and fabric they created in the IFM lab. Photo: Freyla Ferguson/IFM

A materials breakthrough

This research, led by Dr Allardyce and Mr Zaki, with expert input from Sheffield University's Professor Chris Holland, involves sidestepping degumming - a commonplace industrial process - and experimenting with dissolving whole silk fibres.

Using this new technique, the team were able to produce a spinnable solution that better imitates silk as it is produced by the silkworm. This solution was wet spun using IFM's state-of-the art pilot fibre and textile facility to produce fibres that more closely matched natural silk.

According to IFM's Deputy Director Joe Razal, the team's discovery is a world first and demonstrates how IFM researchers are creating new sustainable materials that have real-world application and impact.

'Ben and Martin challenged the norm by creating silk fibres in a laboratory setting,' Professor Razal said.

'They wet spun a cocktail of solubilised, non-separated silk components that mimic the properties produced in nature.'

'The team identified a way to recreate the fibre produced by the silkworm and unlock the potential for it to be just as biodegradable, tough and energy efficient. In fact, when spun under identical conditions, undegummed solutions produces fibres 8 times stronger and 218 times tougher than degummed silk feedstocks.'

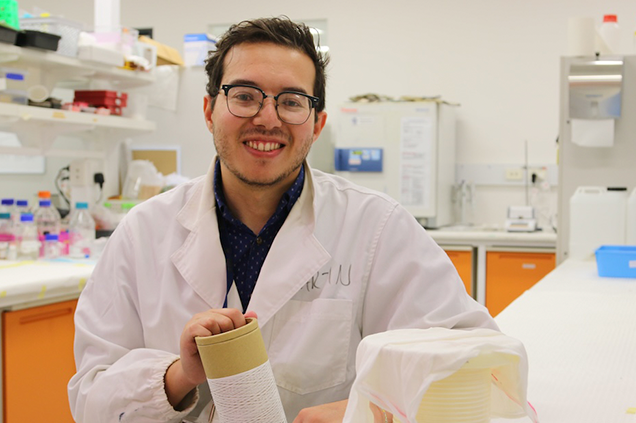

PhD candidate Mr Martin Zaki with the undegummed silk fibre. Photo: Freyla Ferguson/IFM

Undegummed versus degummed silk

'Traditionally, industry has used degumming to unravel the silkworms cocoon to produce their fibres. It is also commonly used by researchers to facilitate "unspinning" silk back into a solution that can then be solidified into new forms,' Professor Holland said.

'However removing a key component to the natural material, the sericin gum coating, often comes with collateral damage to the silk proteins and so it's often considered a necessary evil.'

Mr Zaki explains that the team wanted to produce better materials while simultaneously understanding how.

'We took a step back and asked why has no one attempted this? Is it because it is too hard, or because everyone degums silk and no one has considered doing something different?

In industry, the largest portion of water waste, labour, and energy consumption usually comes from the degumming process. By-passing this step, we increase the potential of a more sustainable technology.'

'Undegummed cocoons are normally insoluble,' adds Dr Allardyce. 'Our innovative process combines a milling step followed by a supersaturated solvent that enables dissolution.'

'No-one has attempted to artificially spin undegummed silk before. And no-one has ever successfully dissolved undegummed cocoons and re-spun them in this way.'

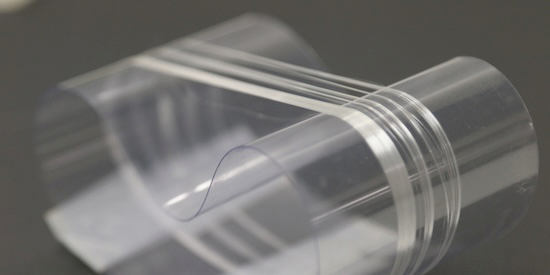

The undegummed silk fibre. Photo: Freyla Ferguson/IFM

Future applications

Degummed silk is used in nerve repair, coating foods to improve shelf-life and biodegradable batteries.

This ground-breaking research forges a new pathway to recreate a fibre with structures akin to native silk.

Dr Allardyce maintains that it's also an innovation that could apply to other next generation fibres.

'If the knowledge could be applied to other biopolymers - other proteins, cellulosic fibres - we could potentially produce new fibres that have a fraction of the energy input to synthetics but perform just as well while retaining the advantage of biodegradability.'

The text of this article is licensed under the Creative Commons Attribution (CC BY) 4.0 International