We along with Cambridge Crystallographic Data Centre (CCDC) have secured funding as part of an Innovate UK grant to advance sustainable pharmaceutical manufacturing.

In this pioneering project, our researchers will play a crucial role in generating experimental data on crystal growth, supporting the validation of cutting-edge digital tools designed to improve drug development.

Revolutionary 3D crystal growth experiments

Researchers from our top-rated Chemistry department will provide essential experimental data to refine the ADDICT software, a predictive tool for crystallisation processes.

Unlike conventional methods, our advanced experimental set-up allows scientists to assess crystal growth rates in three dimensions, offering a more accurate representation of how pharmaceutical particles develop.

By studying the impact of factors such as temperature, solvent choice, and supersaturation on crystal formation, our research will help ensure that digital models reflect real-world conditions.

This will enable pharmaceutical companies to design crystallisation processes with greater precision, reducing the reliance on inefficient trial-and-error methods.

Crystal growth database

In addition to experimental work, we will collaborate with Dr Simon Black, a partner in the project, to develop a unique first of its kind database of crystal growth rates.

This resource will serve as a benchmark for future research, providing valuable data to scientists worldwide who seek to optimise drug manufacturing processes.

By integrating these insights into the CCDC's Mercury platform, the project will make advanced crystallisation tools more accessible to non-specialist scientists, accelerating the pharmaceutical industry's transition towards more sustainable production methods.

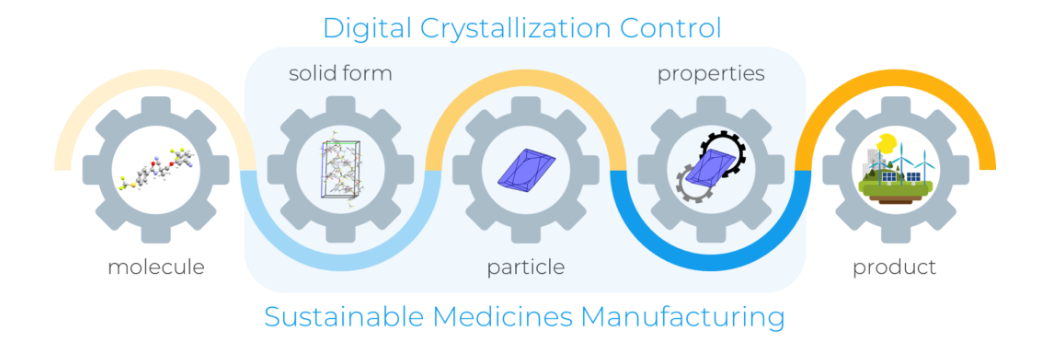

Image - Digital tools can help scientists to predict crystallisation outcomes under a range of experimental conditions, streamlining manufacturing workflows and helping to bring new medicines to patients more sustainably.