A new theory predicts one of the effects of macroscopic mechanical forces on mechanochemical organic synthesis by a ball mill.

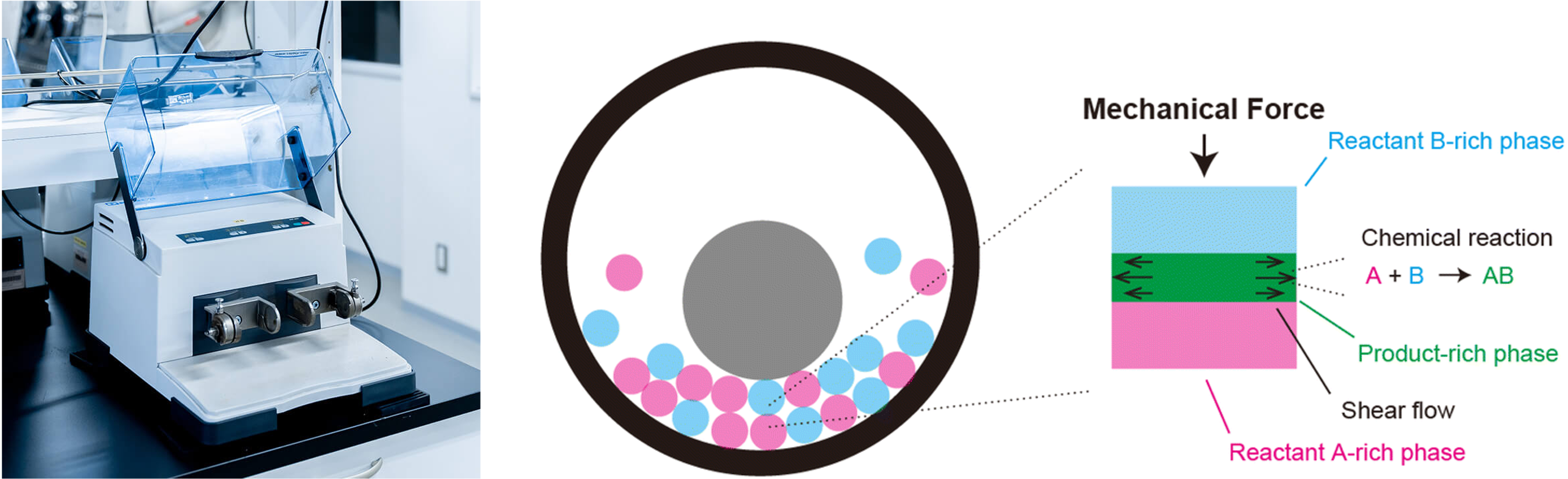

(left) Example of a ball mill apparatus used for mechanochemical reactions. (right) A schematic diagram of a mechanochemical reaction using a ball mill and the influence of mechanical force on the formation of products from reactants. (Photo: Ito lab; Illustration: Tetsuya Yamamoto, et al. RSC Mechanochemistry. December 7, 2024)

In contrast to conventional organic synthesis, mechanochemistry does not use solvents that eventually become industrial wastes. Thus, mechanochemistry is environmentally friendly and enables us to perform organic synthesis using reactants that poorly dissolve into common solvents. As solvents are not used, reactants used for organic synthesis are often solid state. Previous experimental studies have suggested that the force applied by the ball to the system accelerates the chemical reaction, but it is not well understood how macroscopic forces influence chemical reactions on the molecular scale.

Compared to conventional methods for organic synthesis, the theoretical foundation of mechanochemical organic synthesis is still in its infancy. A deeper understanding of reaction kinetics within mechanochemical reactions will be crucial for advancing the field towards becoming a conventional strategy itself.

To this end, a research team led by Associate Professor Tetsuya Yamamoto at the Institute for Chemical Reaction Design and Discovery (WPI-ICReDD), Hokkaido University, has developed a theory that predicts reaction rates in mechanochemical organic reactions using a ball mill. Their work, published in the journal RSC Mechanochemistry, was accomplished through a collaboration between researchers specializing in organic chemistry and rheology.

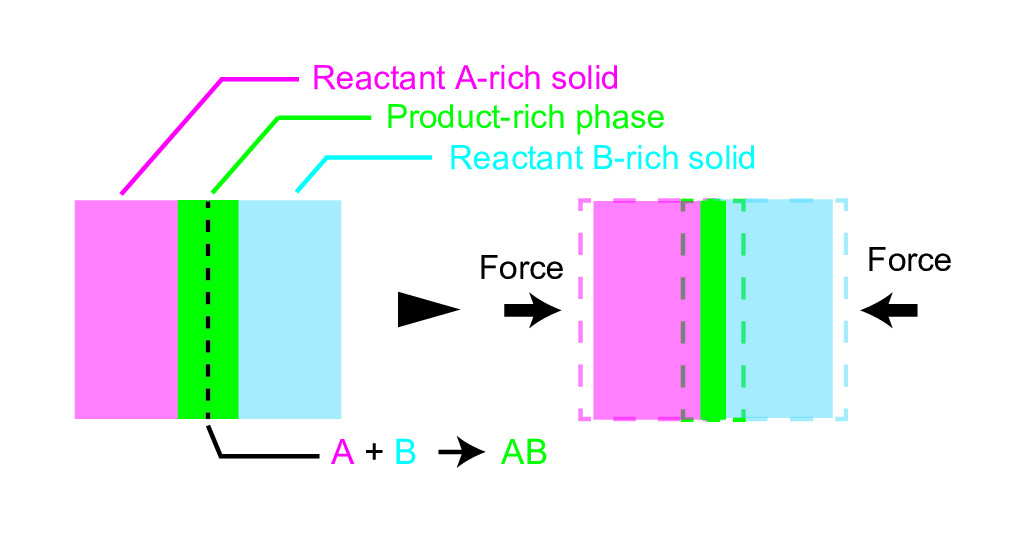

Applied mechanical force in a ball mill enhances the mixing of reactants by decreasing the thickness of the product-rich phase. (Tetsuya Yamamoto, et al. RSC Mechanochemistry. December 7, 2024)

Chemical reactions between solid reactants occur at the interface between them to form a product. The new theory predicts that a layer containing mostly products formed at this interface determines the reaction rate. The theory predicts a cause for reaction acceleration: due to the balls colliding, a force is applied to the interface of the reactants, where the product is formed. This force reduces the thickness of the product-rich layer, and induces faster collisions between reactants, leading to increased product formation.

"This study is the first attempt to make a kinetic theory of mechanochemical reaction by focusing on interfaces. It will form the basis to develop theories to provide further insight into the mechanism of reaction acceleration by applied mechanical forces," said the study's first author, Associate Professor Tetsuya Yamamoto. "The detailed reaction mechanisms of mechanochemical processes remain largely enigmatic. Experimental approaches alone have proven insufficient to fully elucidate these mechanisms. However, through an outstanding collaboration at WPI-ICReDD, we have successfully developed a preliminary theoretical framework to better understand the role of mechanical forces in driving mechanochemical reactions," said the study's second author, Associate Professor Koji Kubota.

(From left) Tetsuya Yamamoto, Koji Kubota, Yu Harabuchi, and Hajime Ito of the research team. (Photo: WPI-ICReDD)

Original Article:

Tetsuya Yamamoto, et al. Scaling theory for the kinetics of mechanochemical reactions with convective flow. RSC Mechanochemistry. December 7, 2024.

DOI: 10.1039/D4MR00091A

Funding:

This work was supported by Japan Society for the Promotion of Science (JSPS) KAKENHI (24H00453, 24H01832, 24H01050, 22K18333, 22H00318); the Japan Science and Technology Agency (JST) CREST (JPMJCR19R1) and JST FOREST (JPMJFR201I, JPMJFR2221); and by the Institute for Chemical Reaction Design and Discovery (WPI-ICReDD), which has been established by the World Premier International Research Initiative (WPI), Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan.