A full trial assembly of a specialist air communications tower for a British Antarctic Research Station has been constructed this autumn in Scotland, ahead of its shipping to Antarctica this month.

Mocking-up the huge communications tower was no mean feat as the roof level is over 16m above ground, with a floor area of over 43.23m2. It is part of the new world-class science and operations facility, the Discovery Building at Rothera Research Station. The Discovery Building Communications Tower will be the station's main communications hub with air-ground communications and monitoring of air traffic for science teams across Antarctica.

The unusual and complex trial assembly was undertaken in Kintore at a specialist construction company, e-Group, on behalf of the Antarctic Infrastructure Modernisation Partnership (AIMP) that are working on upgrading old Antarctic buildings for future generations of polar scientists. The partnership includes construction partner BAM, design consultants Sweco, and Hugh Broughton Architects providing delivery design. Ramboll is acting as Technical Advisors, with architects NORR providing concept design.

The "Flat-Pack" Discovery Building Communications Tower

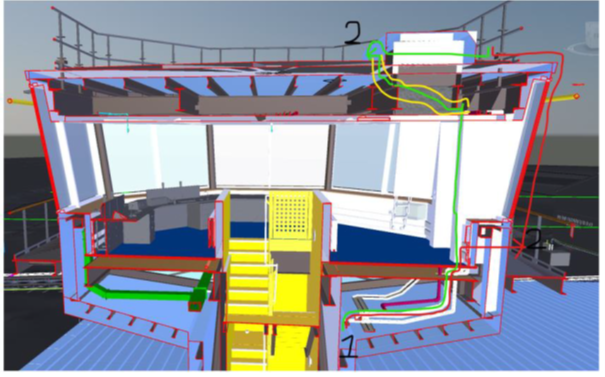

The assembly included installation of both primary and secondary steel with the aim to coordinate design of the steelwork with the stairwell and curtain walling (non-structural outer envelope to keep the weather out and people in, such as window glazing), as well as mitigate risk with installation on site. Minor adjustments were needed to the primary steelwork as one of the beams was reducing headroom on the stairwell. Corrections were also made to the alignment of the secondary steel such as location of fixing holes. Finally, the trial assembly rectified an installation risk with the non- curtain walling clashing with the lifting points.

The Communications Tower height and glazing is set at 9° (angle to shed water quickly and to minimise reflections on the glass) around all sides of the octagonal structure and provides operators with full 360o view of the station and aircraft. This is a vital component to the success of the modernisation of the station.

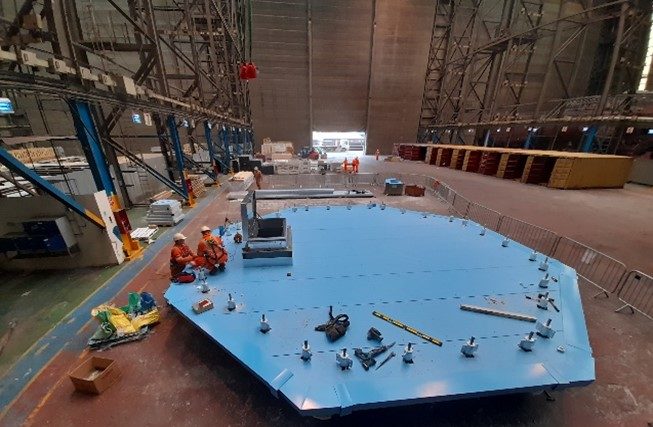

Following its trial assembly, the Communications Tower was 'flat packed' and delivered to BAM's packing facility at Teesport. Here the roof membrane was laid, and access hatch installed by A J Engineering. A non-slip membrane was applied and fixing points for the railing that will run along the perimeter of the roof, allowing operators to access the aerials to be installed on the roof. Prefabricating the roof structure of the Communications Tower in a controlled environment in the UK ensures the roof is finished to the required quality and will significantly reduce the resource time on-site.

The final piece of the Discovery Building Communications Tower jigsaw is the furniture. Following their involvement with the design and manufacture of the control room console at Halley VI Research Station, Thinking Space Systems Ltd were selected by BAM to supply this at Rothera. The purpose of the console is to provide appropriate desk space for operators, but also to house the front-end communications equipment and monitors to manage air traffic and communications with teams operating across the Antarctic.

This bespoke item has been designed ergonomically and is specifically for users who will often be spending long shifts working in the tower managing air control for the station and the busy runway. Spanning six meters in total with four workstations, the control room will be installed over five sides of the octagonal tower. This gives the users uninterrupted views of the runway and most of the Antarctic station.

Build-it-before you build it approach

The benefits of this complex construction process has allowed us to verify that the building's structural design has been suitably designed to meet the operational requirement and helped us to identify any potential construction challenges before getting to site.

BAM Project Manager, Maurice Siemensma says:

"BAM's "build-it-before you build it" approach has involved design and building the structure virtually using 3D modelling, then completion of trial assembly in Scotland prior to actual construction in Antarctica."

It has provided the team with the opportunity to make some small improvements to the structure and curtain wall glazing system, that means we can take greater assurance the structure will be installed without difficulty or delays on Station. Once in Antarctica, it is impossible to make any changes.

Rothera Modernisation Senior Project Manager, David Brand, sums it up by saying:

"The completion of the trial assembly in the UK shows the best of the AIMP construction partnership. Being able to work hand-in-hand with BAM and its supply chain throughout the design, pre-fabrication and developing the construction methodologies gives BAS the assurance that every effort has been directed to ensuring we get the quality the Discovery Building so deserves.

It has been a huge team effort but one that we are sure will reap significant benefits for BAS and the polar science community".