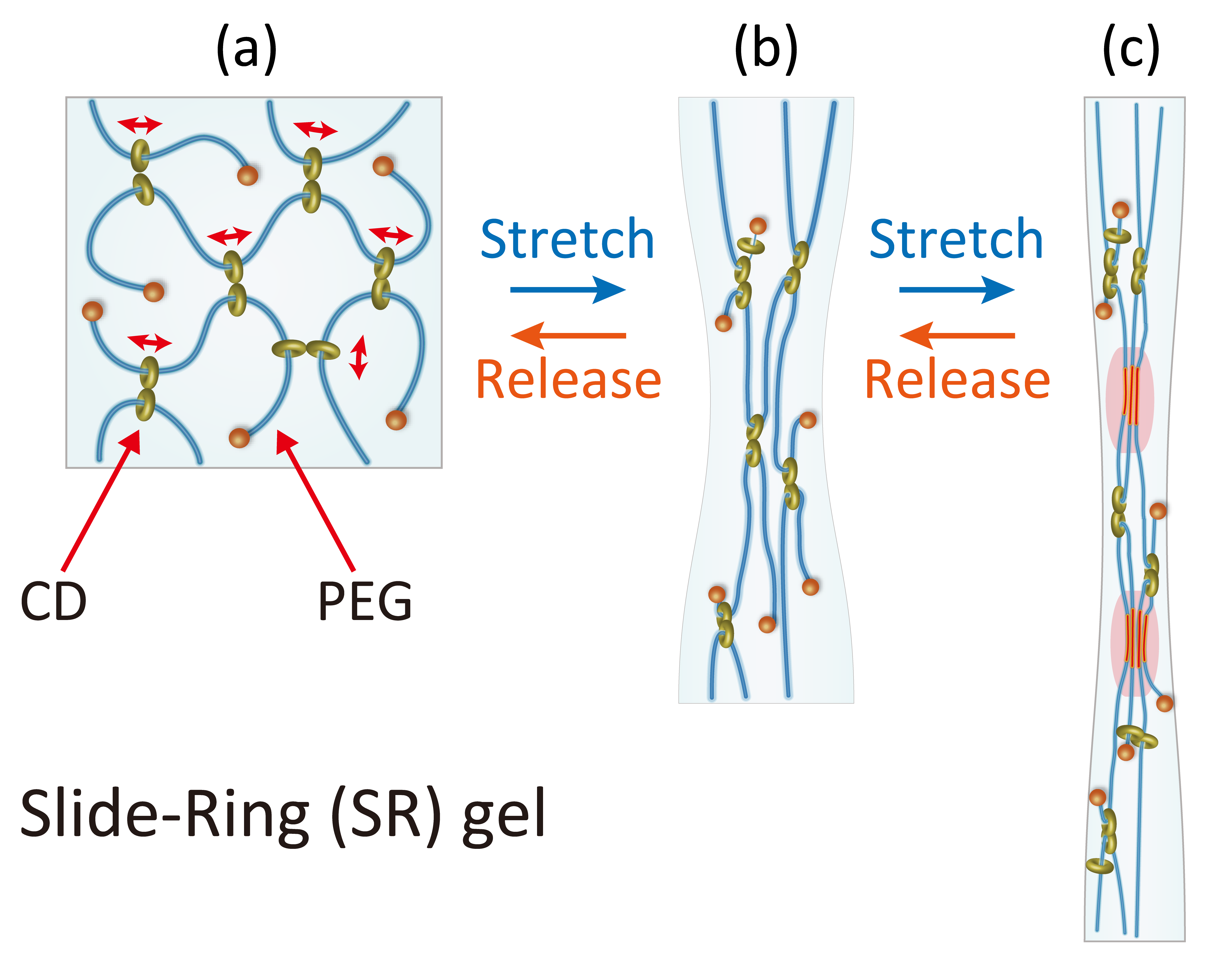

Self-reinforced gel. A strain gauge pulls apart samples of hydrogel. (Upper) A typical gel with a notch cut into the left-hand side snapped soon after it was stretched. (Middle) The new self-reinforced gel had a notch cut into the left-hand side, and despite this it maintained integrity when stretched further than a typical hydrogel. (Lower) A diagram of the polyethylene glycol (PEG) chains and hydroxypropyl-α-cyclodextrin (HPαCD) rings stretching and relaxing . ©2021 Mayumi et al.

Hydrogels are polymer materials made mostly from water. They can be used in a wide range of medical and other applications. However, previous incarnations of the materials suffered from repeated mechanical stress and would easily become deformed. A novel crystal that can reversibly form and deform, allows hydrogels to rapidly recover from mechanical stress. This opens up the use of such biocompatible materials in the field of artificial joints and ligaments.

Many of us suffer the occasional sports injury or experience some kind of pain relating to joints and ligaments at some point in our lives. For serious injuries of this nature, there is often little that can be done to repair the damage. But a new development in the field of water-rich polymer materials known as hydrogels could find its way to the operating room in around 10 years or so. And they should stand up to the same mechanical stresses our natural joint and ligament tissues experience too. They're called self-reinforced gels.

"The problem with existing hydrogels is that they can be mechanically weak and so need strengthening," said Associate Professor Koichi Mayumi from the Institute for Solid State Physics at the University of Tokyo. "However, previous methods to toughen them up only work a limited number of times, or sometimes just once. Those gels do not recover rapidly from stresses such as impacts well at all. So we looked at other materials which do show strong recoverability, such as natural rubber. Taking inspiration from these, we created a hydrogel that exhibits rubberlike toughness and recoverability whilst maintaining flexibility."

Old gel, new gel. These images were taken using polarized, or twisted, light to visualize areas undergoing stress. (Left) A typical hydrogel has snapped under stress while (right) the self-reinforced gel stretches in spite of the stress, highlighted in red. ©2021 Mayumi et al.

Previous examples of toughened hydrogels use so-called sacrificial bonds which break when deformed. The destruction of the sacrificial bonds would dissipate mechanical energy giving the material strength, but the sacrificial bonds would take time, sometimes minutes, to recover. And sometimes they would not recover at all.

In contrast, Mayumi and his team introduced crystals which assemble into rigid shapes under strain, but very quickly revert back to a gel state when the strain is released. In other words, the overall hydrogel is extremely flexible at rest but firms up on impact, much like natural rubbers do. The crystalline structures are composed of polyethylene glycol (PEG) chains bound by hydroxypropyl-α-cyclodextrin (HPαCD) rings in a water-based hydrogel.

"As hydrogels are over 50% water, they are considered highly biocompatible, essential for medical applications," said Mayumi. "Our next stage of research is to try different arrangements of molecules. If we simplify our structures, then we can reduce the cost of materials which will also help accelerate adoption of them by the medical industry."