Ever shorter product life cycles and volatile markets force companies to produce high-quality products quickly with new, immature processes. Like software that is continuously developed during its application, production processes are being improved during their operation. This is what researchers of Karlsruhe Institute of Technology (KIT) and Fraunhofer-Gesellschaft at Karlsruher Forschungsfabrik - The Karlsruhe Research Factory for AI-integrated Production are working on. With the help of Artificial Intelligence (AI), they want to significantly shorten the time it takes to introduce new products to the market and save costs.

Companies need mature production processes for cost-efficient and high-quality production. As many different factors have to be considered, process development has always been time-consuming, especially when new materials and methods are used, when the production process is highly complex, or when there is a lack of fully developed models. The goal of the research group "AI-based Methodology for the Rapid Upgrading of Immature Production Processes" of KIT and Fraunhofer-Gesellschaft is to systematically use AI to make improving processes cheaper, faster, and more efficient. This would make it easier for companies in fields like lightweight engineering or electromobility to grasp new production processes in their entirety and adjust and improve them accordingly. Using the example of fiber-reinforced plastic component production for areas like the automobile sector, the team wants to demonstrate how AI methods allow for an increase in process maturity and product quality in a short time and with ongoing operations.

Optimizing Processes and Over-instrumentation: How to make AI learn faster

"We are starting by looking at the process of reshaping semi-finished fiber parts. These are flat fabrics used as raw materials when producing components. Currently, it is necessary to manually rework them by reheating or reshaping until the correct process parameters and steps are found and implemented," explains Professor Jürgen Beyerer, who holds a chair at KIT's Institute for Anthropomatics and Robotics and is director of the Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB. "The goal is to understand the process as quickly as possible and to adjust the process based on this in order to begin producing high-quality products earlier."

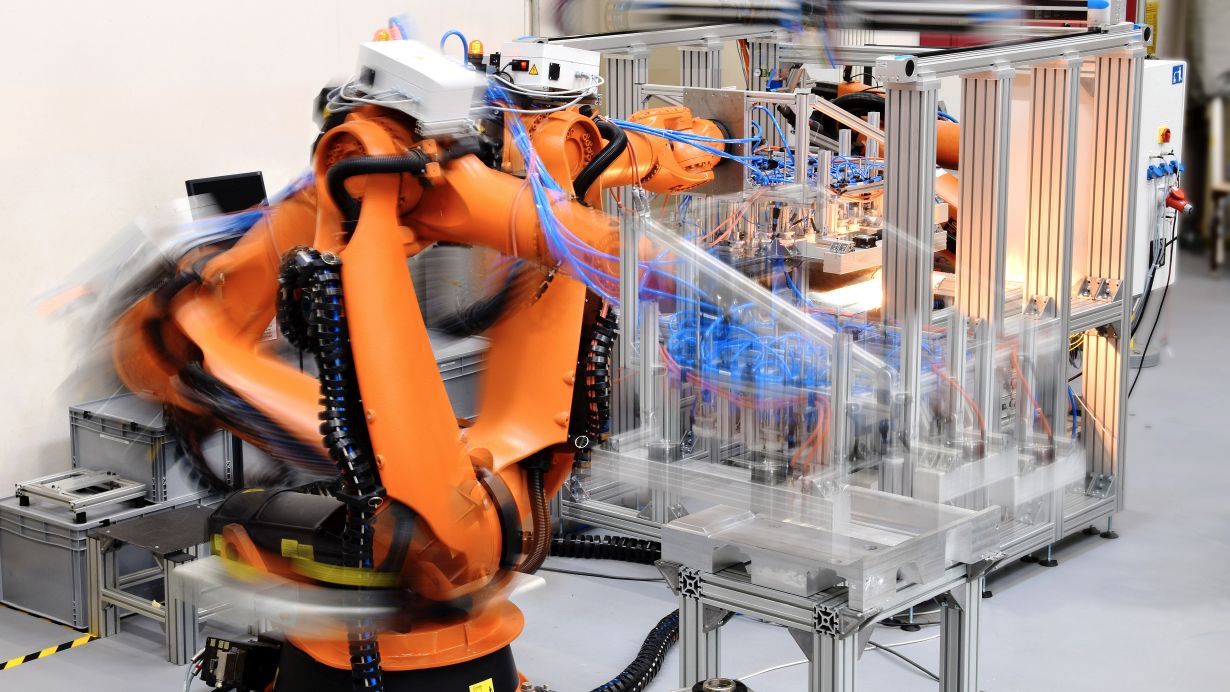

To achieve this, the team adds an extended range of actuators and sensors - for instance, robotic parts and additional measuring instruments. This technique is called "over-instrumentation." It involves getting as much information on temperatures, pressures, and forces as possible. Depending on the prediction made by the independently learning model, parameters can be identified that are necessary to control the process. "We will systematically outfit immature processes in such a way that an AI can learn relatively quickly how process parameters and results are connected," Beyerer says.

Adjusting Processes: AI Gives Suggestions

To avoid repeating this procedure for every new process, the researchers are trying to generalize the findings and develop an assembly kit that can be applied to any similar process. Using dynamic modeling, a digital image of the process will be created to test out the database in advance. "The resulting estimate for a quick maturing of not fully specified production processes also enables a quick transfer of research results into the industry. Companies receive a method to adjust processes and to measure the process maturity," states Professor Jürgen Fleischer, Head of KIT's wbk Institute of Production Science.

With their new approach, the research group won out against fierce competition: The German Research Foundation (DFG) funds them with 4.79 million euros for four years as one of eight groups in the strategic artificial intelligence funding initiative, endowed with 90 million euros. After a successful review, an extension for another four years is scheduled. There are doctoral positions in the fields of mechanical engineering, informatics, mechatronics, and business engineering to be created for this project. The research group will begin working on January 1, 2023.