A group of researchers from Tohoku University has unveiled a new material that exhibits enormous magnetoresistance, paving the way for developments in non-volatile magnetoresistive memory (MRAM).

Details of their unique discovery were published in the Journal of Alloys and Compounds on May 29, 2023.

Today, the demand for advancements in hardware that can efficiently process large amounts of digital information and in sensors has never been greater, especially with governments deploying technological innovations to achieve smarter societies.

Much of this hardware and sensors rely on MRAM and magnetic sensors, and tunnel magnetoresistive devices make up the majority of such devices.

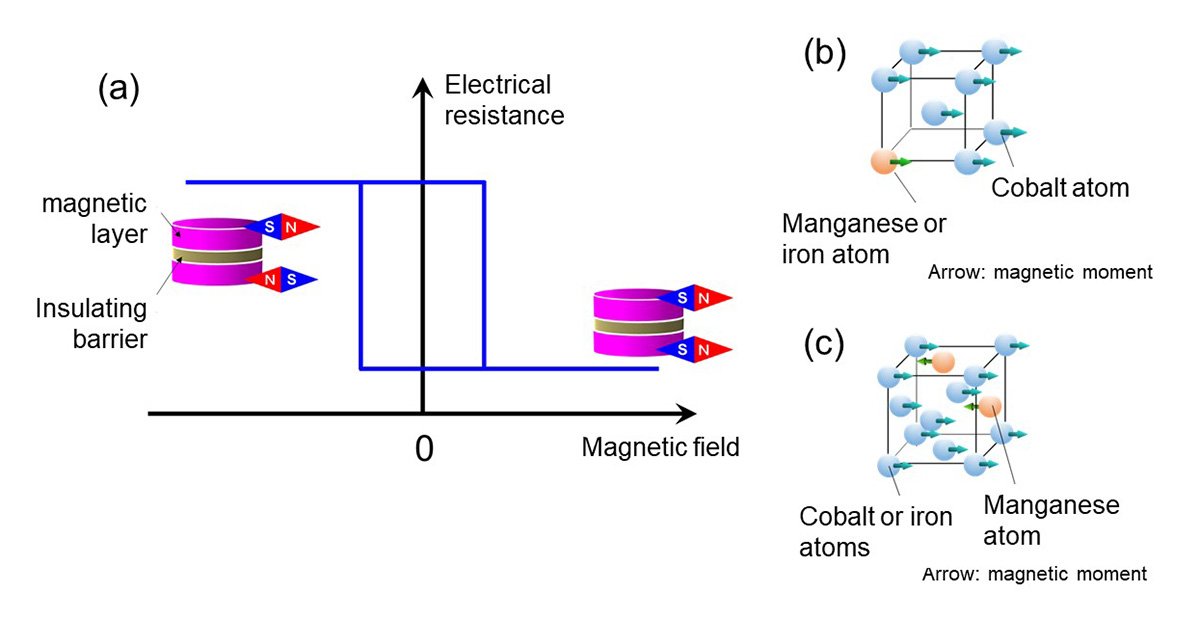

Tunnel magnetoresistive devices exploit the tunnel magnetoresistance effect to detect and measure magnetic fields. This is tied to the magnetization of ferromagnetic layers in magnetic tunnel junctions. When the magnets are aligned, a low resistance state is observed, and electrons can easily tunnel through the thin insulating barrier between them. When the magnets are not aligned, the tunneling of electrons becomes less efficient and leads to higher resistance. This change in resistance is expressed as the magnetoresistive ratio, a key figure in determining the efficiency of tunneling magnetoresistive devices. The higher the magnetoresistance ratio, the better the device is.

Current tunnel magnetoresistive devices comprise magnesium oxide and iron-based magnetic alloys, like iron-cobalt. Iron-based alloys have a body-centered cubic crystal structure in ambient conditions and exhibit a huge tunnel magnetoresistance effect in devices with a rock salt-type magnesium oxide.

There have been two notable studies using these iron-based alloys that produced magnetoresistive devices displaying high magnetoresistance ratios. The first in 2004 was by the National Institute of Advanced Industrial Science and Technology in Japan and IBM; and the second came in 2008, when researchers from Tohoku University reported on a magnetoresistance ratio exceeding 600% at room temperature, something that jumped to 1000% with temperatures near zero kelvin.

Since those breakthroughs, various institutes and companies have invested considerable effort in honing device physics, materials, and processes. Yet aside from iron-based alloys, only some Heusler-type ordered magnetic alloys have displayed such enormous magnetoresistance.

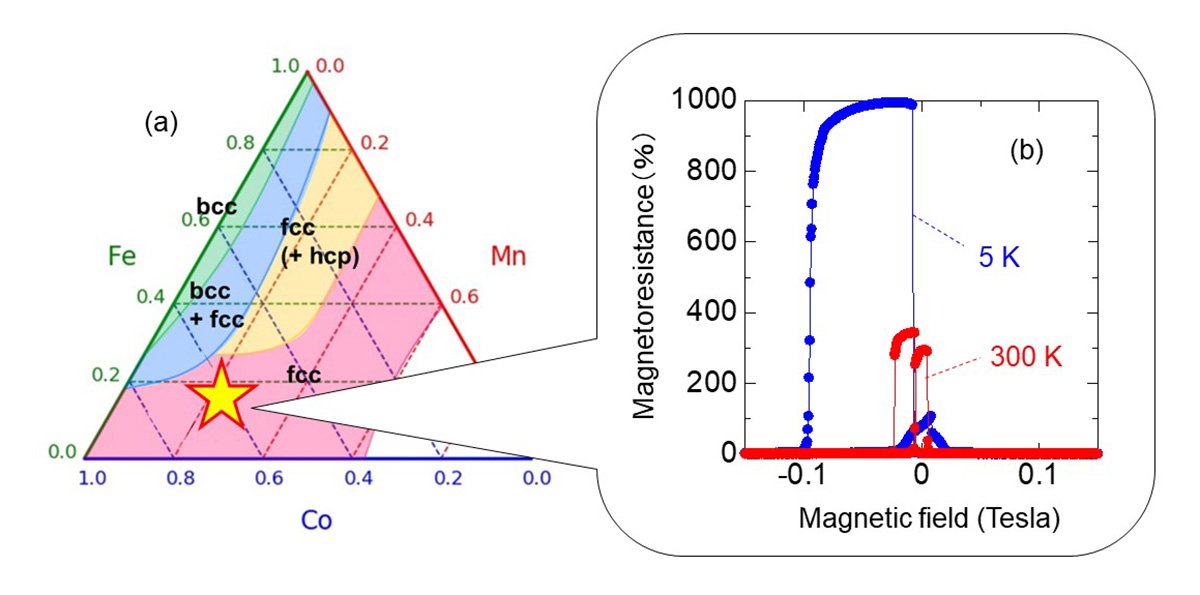

Dr. Tomohiro Ichinose and Professor Shigemi Mizukami from Tohoku University recently began exploring thermodynamically metastable materials to develop a new material capable of demonstrating similar magnetoresistance ratios. To do so, they focused on the strong magnetic properties of cobalt-manganese alloys, which have a body-centered cubic metastable crystal structure.

"Cobalt-manganese alloys have face-centered cubic or hexagonal crystal structures as thermodynamically stable phases. Because this stable phase exhibits weak magnetism, it has never been studied as a practical material for tunnel magnetoresistive devices," said Mizukami.

Back in 2020, the group reported on a device that used a cobalt-manganese alloy with metastable body-centered cubic crystal structure.

Using data science and/or high-throughput experimental methods, they built upon this discovery, and succeeded in obtaining huge magnetoresistance in devices by adding a small amount of iron to the metastable body-centered cubic cobalt-manganese alloy. The magnetoresistance ratio was 350% at room temperature and also exceeded 1000% at a low temperature. Additionally, the device fabrication employed the sputtering method and a heating process, something compatible with current industries.

"We have produced the third instance of a new magnetic alloy for tunneling magnetoresistive devices showing huge magnetoresistance, and it sets an alternative direction of travel for future improvements," adds Mizukami.

- Publication Details:

Title: Large tunnel magnetoresistance in magnetic tunnel junctions with magnetic electrodes of metastable body-centered cubic CoMnFe alloys

Authors: Tomohiro Ichinose, Junichi Ikeda, Yuta Onodera, Tomoki Tsuchiya, Kazuya Z. Suzuki, and Shigemi Mizukami

Journal: Journal of Alloys and Compounds