For Lee English Jr., the sound of a ringing phone probably sounds a lot like the roar of a rocket engine test at NASA's Stennis Space Center near Bay St. Louis, Mississippi.

During the 1970s, when 9-year-old English Jr. picked up the ringing phone, someone from the south Mississippi test site might say, "Tell your dad we just dropped LOX."

The caller was referring to the liquid oxygen propellant used to help fuel a new space shuttle engine undergoing developmental testing at NASA Stennis.

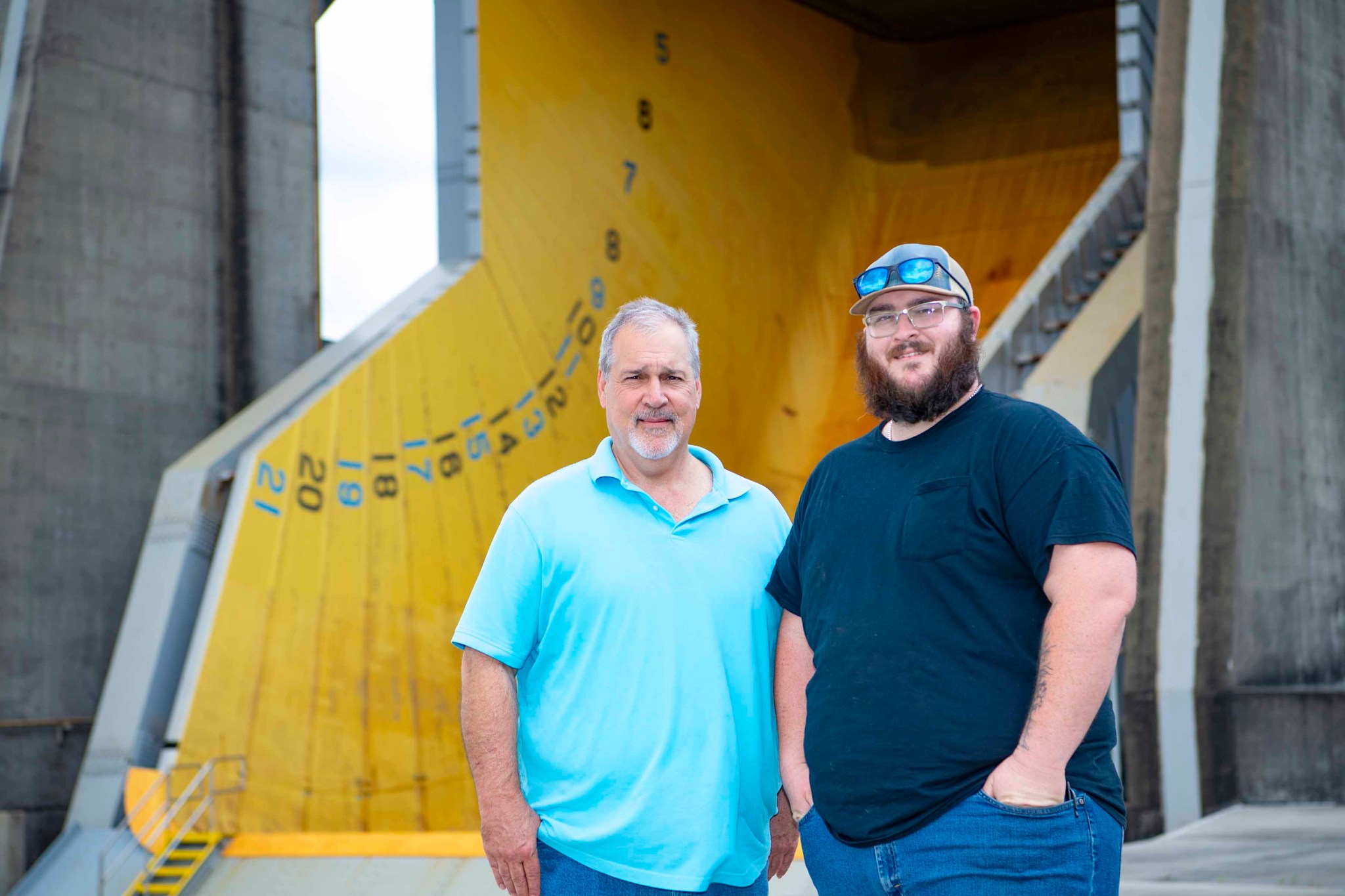

To the English family, NASA Stennis stands alongside cherished family heirlooms. It is a treasured place where one generation helped lead the way for ensuing ones to find career success. Both English Jr. and his son, Noah, have followed in Lee English Sr.'s footsteps to work at NASA Stennis.

English Sr., an engineer working for the Rocketdyne Division of Rockwell International Corporation in the 1970s, moved his family to Mississippi from California when work was just beginning on how to test engines for NASA's new Space Shuttle Program.

He is remembered as a "key guy" who helped develop the testing blueprints. He had to be available for consultation at a moment's notice since testing could happen at all hours, including at night. He also is credited with conducting the first seven space shuttle main engine tests at the Fred Haise Test Stand (formerly A-1 Test Stand).

"Every time we do something new, you don't know what you don't know," said Maury Vander, chief of the NASA Stennis Test Operations Division. "These teams were taking the first steps toward getting an engine ready that was required to make the shuttle successful."

Initial hot fires were one second or less. "There was a lot to learn," Vander said. "The new engine was extremely complicated, taking about 20 tests to achieve a duration of two seconds, then reaching a duration of 10 seconds on test number 42."

Now, a team of operators from NASA; Aerojet Rocketdyne, an L3 Harris Technologies company; and Syncom Space Services (S3) routinely test RS-25 engines for 500 seconds. The evolved version of the space shuttle main engine, manufactured by Aerojet Rocketdyne, helps power NASA's SLS (Space Launch System) rocket for Artemis missions to the Moon and beyond.

From answering the telephone to answering the call to continue a legacy, English Jr., now 60, has worked in various roles for over three decades at NASA Stennis. As an instrumentation technician for S3, he now helps collect and process engine performance data during hot fires.

"There's a sense of pride when you see something you feel like your family has worked towards for lots and lots of years," English Jr. said. "At the time, I'm sure when my dad and the team were doing their work, they never thought we would be using those same engines to try to go to Mars or even back to the Moon."

As English Jr. helps collect data on engine performance, his son, Noah, 28, works with S3 as a senior mechanical technician to support propellant transfer for engine testing.

"This place is special and not only for my family," Noah said. "This place is special for Mississippi. The jobs and opportunity here are a big part of Mississippi. It would be amazing in the future to have a child who works out here and have the legacy continue."

English Sr.'s last visit to NASA Stennis came more than seven years ago. He passed away in 2019 at the age of 88. "He was amazed at how efficient things had gotten over the years," English Jr. recalled. The assessment is a tribute, not only to the groundbreaking work of the original test team but to countless others - like his son and grandson - who have followed and who work daily to ensure NASA Stennis is better than they found it for the benefit of all.