5 min read

Note: The following article is part of a series highlighting propulsion testing at NASA's Stennis Space Center. To access the entire series, please visit: https://www.nasa.gov/feature/propulsion-powering-space-dreams/.

The work of NASA has fueled commercial spaceflight for takeoff - and for many aerospace companies, the road to launch begins at NASA's Stennis Space Center near Bay St. Louis, Mississippi.

Already the nation's largest propulsion test site and a leader in working with aerospace companies to support their testing needs, NASA Stennis aims to continue growing its commercial market even further.

"The aerospace industry is expanding rapidly, and we are here to support it," said NASA Stennis Director John Bailey. "NASA Stennis has proven for more than two decades that we have the versatile infrastructure and reliable propulsion test experts to meet testing needs and accelerate space goals for a whole range of customers."

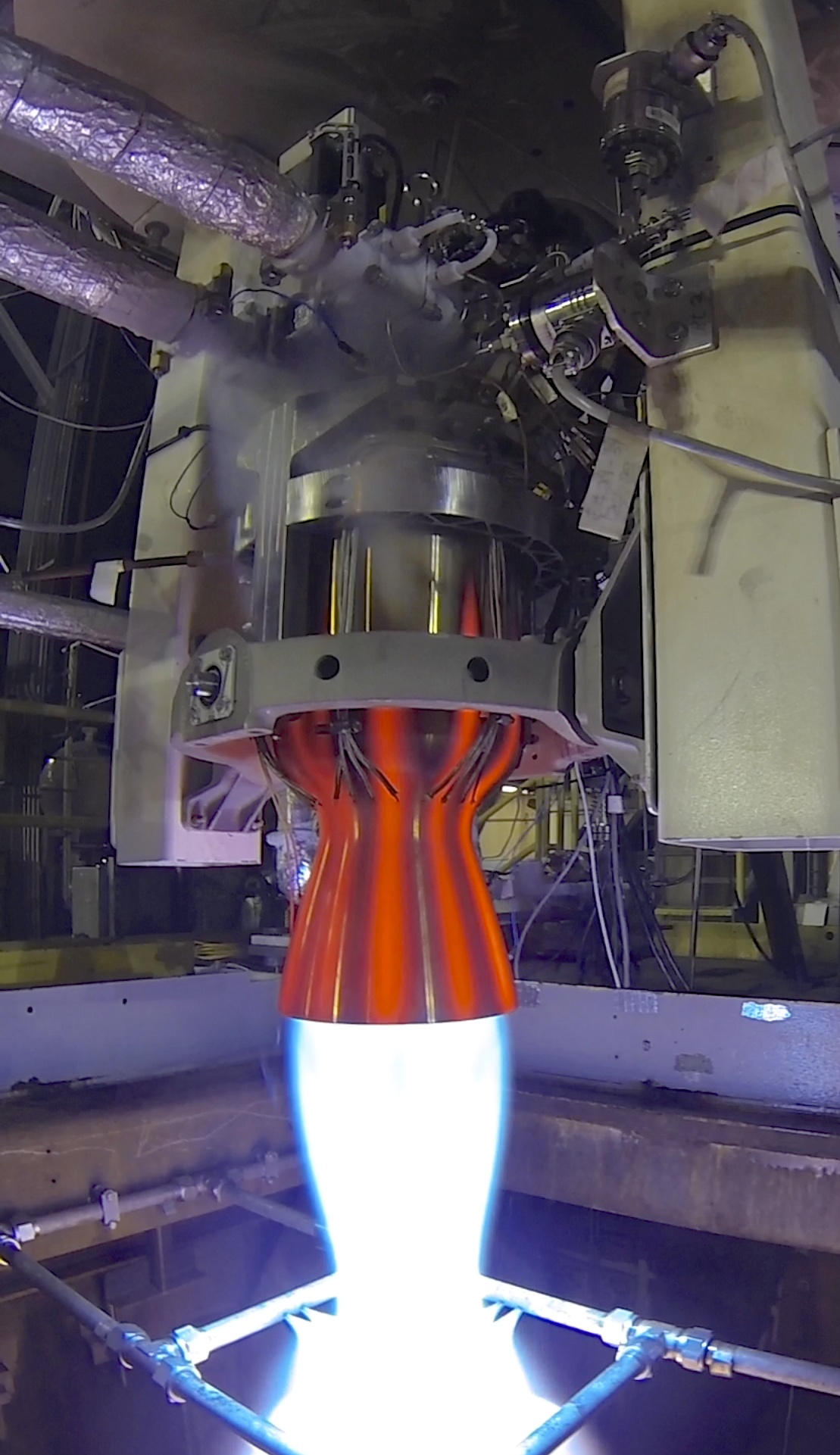

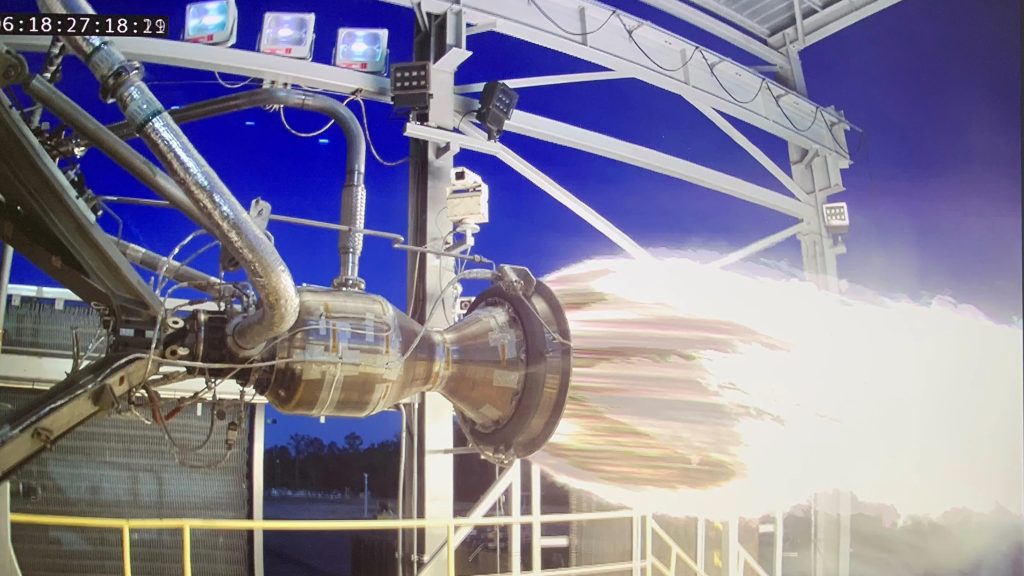

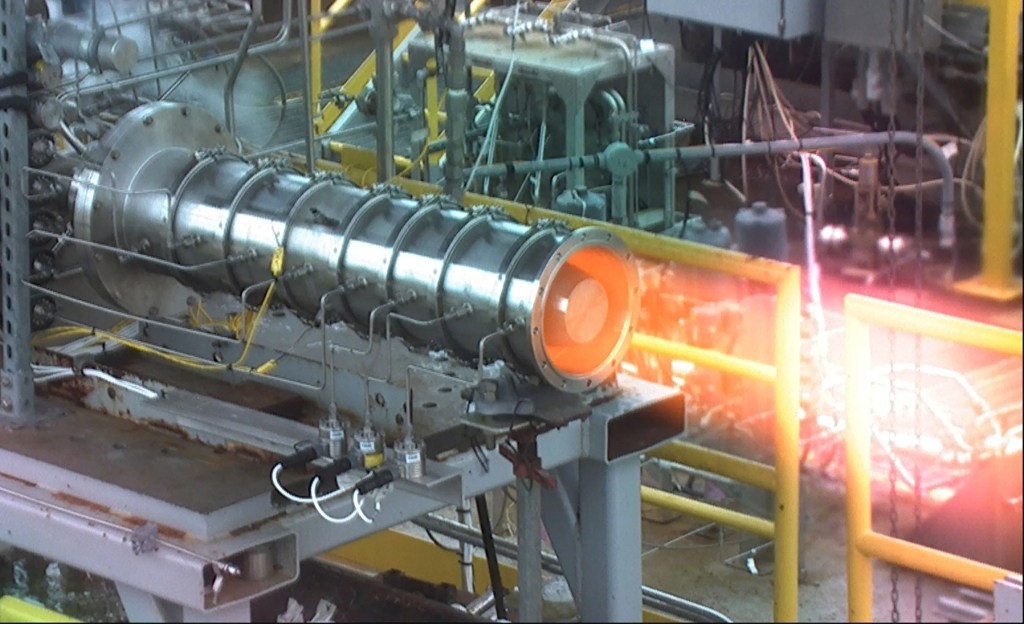

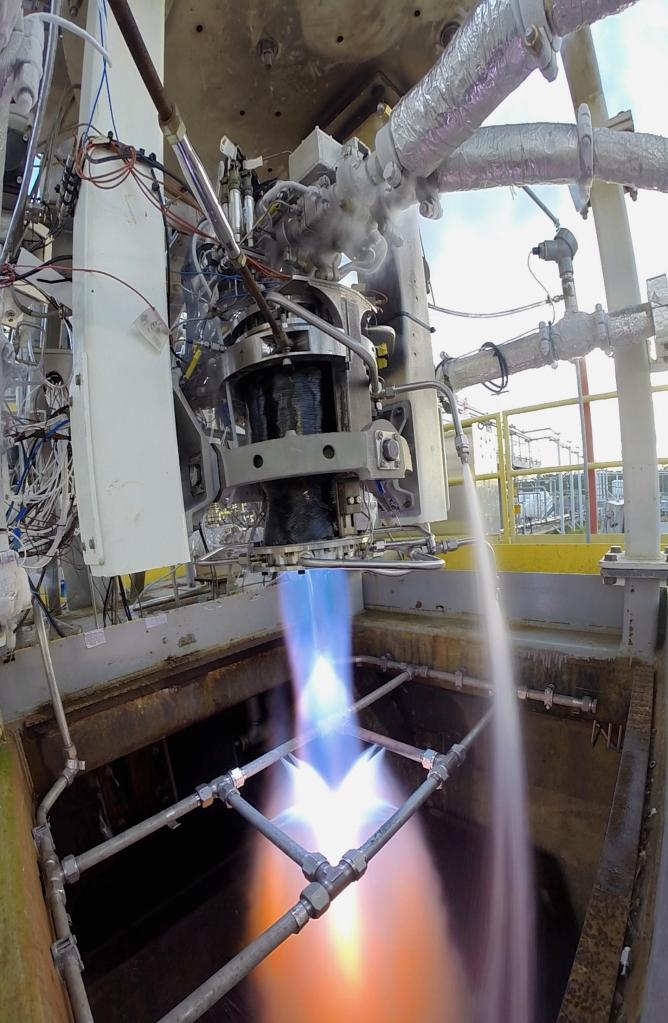

The central hub for meeting those needs at the south Mississippi center is the E Test Complex. It features four stands with 12 test cells capable of supporting a range of component and engine test activities. NASA operates the E-1 Test Stand with four cell positions and the E-3 Test Stand with two cells. Relativity Space, based in Long Beach, California, leases the E-2 and E-4 stands to support some of its test operations.

Developed during the 1990s and early 2000s, the E Test Complex can deliver various propellants and gases at high and low pressures and flow rates not available elsewhere. The versatility of the complex infrastructure and test team allows it to support projects for commercial aerospace companies, large and small. NASA Stennis also provides welding, machining, calibration, precision cleaning, and other support services required to conduct testing.

"NASA Stennis delivers exceptional results in a timely manner with our capabilities and services," said Duane Armstrong, manager of the NASA Stennis Strategic Business Development Office. "Our commercial partnerships and agreements have proven to be true win-win arrangements. NASA Stennis is where customers have access to unique NASA test support infrastructure and expertise, making it the go-to place for commercial propulsion testing."

Companies come to the south Mississippi site with various needs. Some test for a short time and collect essential data. Others stay for an extended period. The stage of development and the particular test article, whether a component or full engine, determine where testing takes place within the E Complex.

NASA Stennis also offers a variety of test agreements. Companies may lease a stand or area and perform its own test campaign. They also may team with NASA Stennis engineers and operators to form a blended test team. And in some cases, companies will turn over the entirety of test work to the NASA Stennis team. Current companies conducting work at NASA Stennis include: Blue Origin; Boeing; Evolution Space; Launcher, a Vast company; Relativity Space; and Rolls-Royce. They join a growing list who conducted earlier test projects in the complex, including SpaceX, Stratolaunch, Virgin Orbit, and Orbital Sciences Corporation.

In addition, three companies - Relativity Space, Rocket Lab, and Evolution Space - are establishing production and/or test operations onsite.

"We may work with a customer brand new to the field, so we help them figure out how to build their engine," said Chris Barnett-Woods, E-1 electrical lead and instrumentation engineer. "Another customer may know exactly what they want, and we support them to make it happen. We focus on customer need. Given our expertise, we know how testing needs to be conducted or can figure it out quickly together, which can help our customer save money toward a successful outcome."

Capabilities to benefit NASA and the aerospace industry have grown since the center entered its first commercial partnership in the late 1990s. The test team also has grown in understanding the commercial approach, and the center has committed itself to adapting and streamlining its business processes.

"Time-to-market is key for commercial companies," said Joe Schuyler, director of the NASA Stennis Engineering and Test Directorate. "They want to test as efficiently and economically as possible. Our goal is to meet them where they are and deliver what they need. And that is exactly what we focus our efforts on."

As stated in the site's latest strategic plan, the goal is to operate as "a multi-user propulsion testing enterprise that accelerates the development of aerospace systems and services by government and industry." To that end, the site is innovating its operations, modernizing its services, and demonstrating it is the best choice for propulsion testing.

"NASA Stennis is open for business as the preferred propulsion provider for aerospace companies," Bailey said. "Companies across the board are realizing they can achieve their desired results at NASA Stennis."