Abstract

A research team, led by Professor Kyeong-Min Jeong in the School of Energy and Chemical Engineering at UNIST has unveiled a revolutionary electrode that is five times thicker than existing models, utilizing the dry process. This advancement not only enhances battery capacity but also maintains rapid charging speeds, aligning with environmental goals by eliminating the use of chemical solvents.

As the demand for high-capacity lithium-ion batteries surges with the rise of electric vehicles (EVs), there is a growing focus on design strategies that maximize electrode thickness while minimizing inactive components. Unfortunately, traditional wet electrode manufacturing methods have struggled to create thicker electrodes, often resulting in clumping during the solvent evaporation stage due to the nature of powder-type electrodes.

In contrast, Professor Jeong's research team successfully engineered an electrode up to five times thicker, achieving a mixture layer density of 3.65 g/cm³, which is directly related to its capacity. The resultant areal capacity of the electrode is an impressive 20 mAh/cm², significantly exceeding that of commercial counterparts.

When integrated into batteries, this innovative electrode could enhance the driving range of electric vehicles by approximately 14 percent. "While conventional electric vehicle batteries have made the journey between Seoul and Busan challenging, our technology has the potential to enable over 600 kilometers of travel on a single charge," stated Professor Jeong.

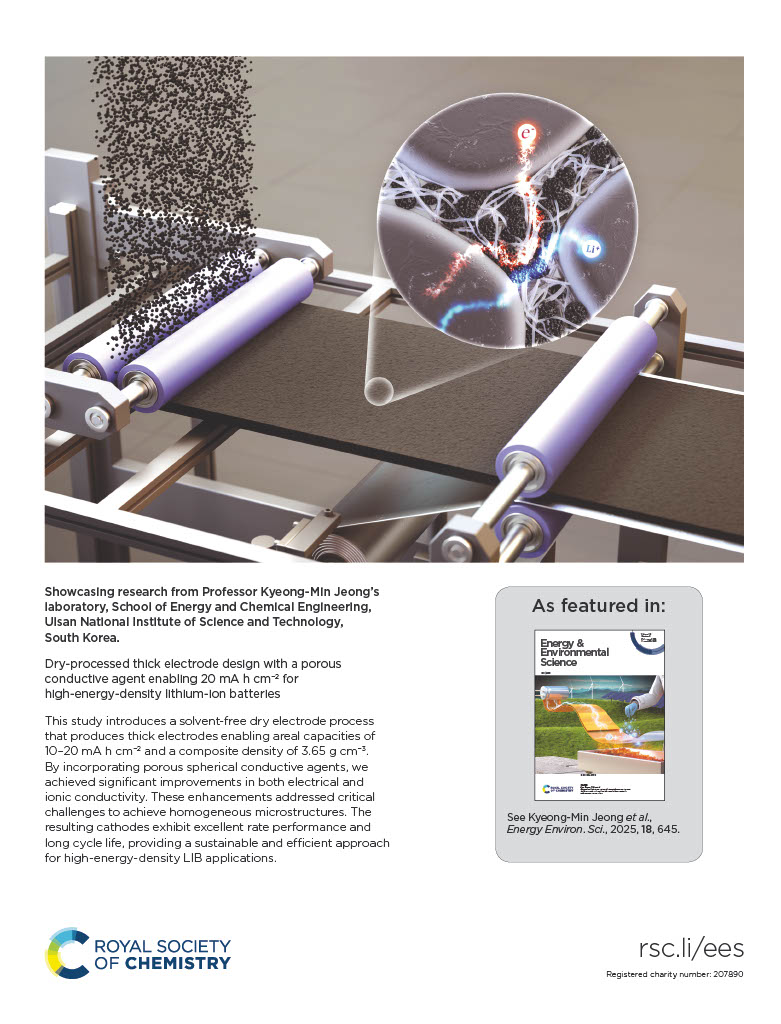

The work by Professor Kyeong-Min Jeong in the School of Energy and Chemical Engineering at UNIST has been featured on the backcover of Energy & Environmental Science (IF 32.4) and published on January 21, 2025.

Additionally, the new electrode design incorporates a porous spherical conductive material that significantly boosts conductivity. In typical scenarios, increased electrode thickness results in longer lithium ion transport distances, thereby reducing output and slowing charging speeds. However, the use of specialized materials like the porous spherical conductive agent can mitigate these challenges, a feat not feasible with traditional wet methods.

"This technology marks a significant breakthrough, advancing both capacity and performance of eco-friendly dry electrodes," remarked Hyesong Oh, the first author of the study. "It is particularly noteworthy for demonstrating the performance of 1 Ah-class pouch cells, paving the way for large-scale production beyond laboratory coin cell experiments."

The findings of this study were featured on the backcover of Energy & Environmental Science (IF 32.4) and published on January 21, 2025. This research was supported by the National Research Council of Science & Technology (NST) and the Ministry of Science and ICT (MSIT).

Journal Reference

Hyeseong Oh, Gyu-Sang Kim, Jiyoon Bang, et al., "Dry-processed thick electrode design with a porous conductive agent enabling 20 mA h cm−2 for high-energy-density lithium-ion batteries," Energy Environ. Sci., (2025).