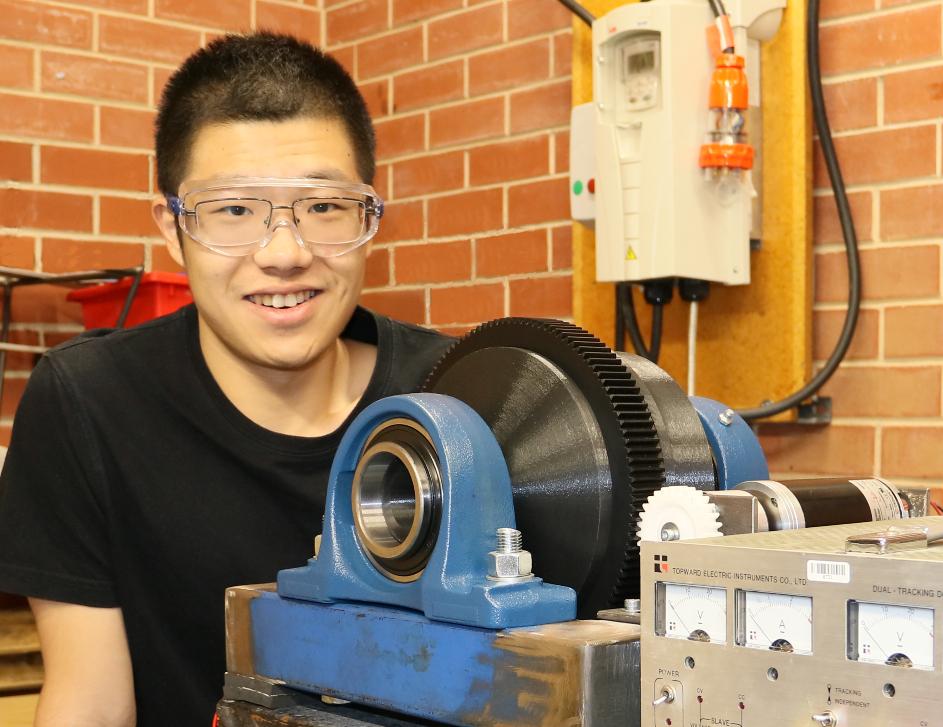

Zeqi Li

A new training centre will deliver the next generation of scientists and engineers in sensors, data analytics and artificial intelligence to increase value in the mining and processing of complex resources.

Launched today, Friday 9 July, the Australian Research Council (ARC) Training Centre for Integrated Operations for Complex Resources (IOCR) brings together end-users, translation partners and researchers.

The four-year $11.75 million project, which involves three universities and 18 industry partners through the ARC Industrial Transformation Research Program, is led by the Director of the Centre, the University of Adelaide's Professor Peter Dowd who is Professor of Mining Engineering at the School of Civil, Environmental and Mining Engineering.

"The ARC Training Centre for Integrated Operations for Complex Resources will deliver the vital enabling tools for automated, integrated and optimised mining," said Professor Dowd.

"As higher grade and more accessible mineral deposits become depleted, mineral resources will be extracted from deeper, lower grade, and more complex ore bodies.

"Maximising the profitability of complex ore bodies requires smarter, more selective practices, tailored to suit each mining operation.

"The Centre will produce future leaders in advanced sensors and data analytics for complex resources."

The Centre, which began operating in August 2020, will equip the next generation of scientists and engineers through mentoring programs, career relevant training, industry placements, collaboration with partner organisations and participation in world-leading inter-disciplinary research.

"As higher grade and more accessible mineral deposits become depleted, mineral resources will be extracted from deeper, lower grade, and more complex ore bodies."Professor Peter Dowd

The Training Centre will:

- Transform end-user mining operations by optimising productivity and product quality and by delivering automated and integrated mining.

- Translate new technological research outcomes to industry-ready applications.

- Increase certainty on product quality.

- Maximise throughput and recovery of minerals in mining operations.

Early career researchers, early career professionals and PhD scholars will be trained at the Centre, which will also run outreach projects promoting STEM to high school students.

The sixteen projects being undertaken by PhD students at the Training Centre will cover all aspects of integrated mining operations from extraction of ore to analysis, to processing through to the final product. The holistic, inter-disciplinary approach to training people in integrated mining operations is unique.

Zeqi Li is a PhD student working on making grinding technology more efficient and less energy intensive.

"I am analysing the performance of a scaled-down version of a Semi-Autogenous Grinding (SAG) mill which is used in mining operations world-wide to break ore into smaller particles," he said.

"The liners inside the SAG mill wear down as ore passes through the mill. Effective systems to monitor this wear ensure the mill is working at optimal efficiency, which in turn reduces the energy required for this part of the mining process."

Reducing the energy consumed by each operation in the mining process will help make resource utilisation more environmentally and commercially sustainable now and in the future.

The Centre brings together end-users, translation partners and researchers to drive productivity in mining, grow competitiveness in the mining equipment, technology services (METS) sector, and build skills and capacity for end-user focussed research.

The project is a collaboration between the University of Adelaide, the University of South Australia and Curtin University, and partners from the mining industry, mining equipment and technical services companies and government.

"Delivering research excellence that directly benefits society is at the core of what the University of Adelaide seeks to achieve," says the University's Vice-Chancellor and President, Professor Peter Høj AC.

"The ARC Training Centre for Integrated Operations for Complex Resources builds on our existing mining and mineral processing research expertise.

"This Centre will help train the next generation of leaders in the mining industry who will tackle the challenge to provide society with the sustainable supply of resources it needs to maintain future prosperity."

Funding for the Training Centre was won by the University of Adelaide's Institute for Mineral and Energy Resources. The Training Centre is supported with $3.7 million from the ARC and a further $8.046 million in cash and in-kind from company, university, government and technology stakeholders across the mining sector.

The project launch will be celebrated at an opening event held at the National Wine Centre attended by representatives from industry and government including South Australian Energy Minister, the Hon. Dan van Holst Pellekaan.

"Mining, energy and resources are critical to the economic and technological future of South Australia and the nation," said Minister van Holst Pellekaan. The Marshall Government understands the mining sector needs the best and brightest minds to ensure its future in an increasingly competitive environment."

The University of Adelaide is collaborating with the University of South Australia and Curtin University to deliver this project. Industry partners are BHP, Boart Longyear, Bureau Veritas, CRC ORE, Datanet, Dassault Systems, Eka Software Solutions, Magotteaux, Manta Controls, Maptek, the Mineral Resources and Heavy Engineering Skills Centre, MZ Minerals, Orica, OZ Minerals, Petra Data Science, RoqSense, Rockwell Automation and Scantech. Supporting organisations are METS Ignited, AMIRA and the South Australian Government.