New industry-linked Swinburne research could save lives and save millions by using nanomaterials to help engineers detect structural defects in planes and rockets before they cause disaster.

The ARC Linkage funded project with Sparc Technologies and Composite Materials Engineering is creating the next generation of smart composites that can improve safety and reliability, while significantly reducing costs in the energy, transport and aerospace sectors.

These smart carbon fibre structures are designed to detect potential failure and assess maintenance needs in real-time, wirelessly using a smart device. We could be seeing this technology in commercial airplanes and wind turbines within the decade.

Deputy Vice-Chancellor Research, Professor Karen Hapgood, said the project was utilising Swinburne's world-leading capabilities and expertise in space, aerospace and advanced manufacturing to make a real-world impact.

"Smart composites, such as those being created by this project, represent the connected future of our cities, our structures and our networks."

"We are delighted to be working with our partners at Sparc Technologies to be turning this research into a reality that can drastically improve safety and reduce costs."

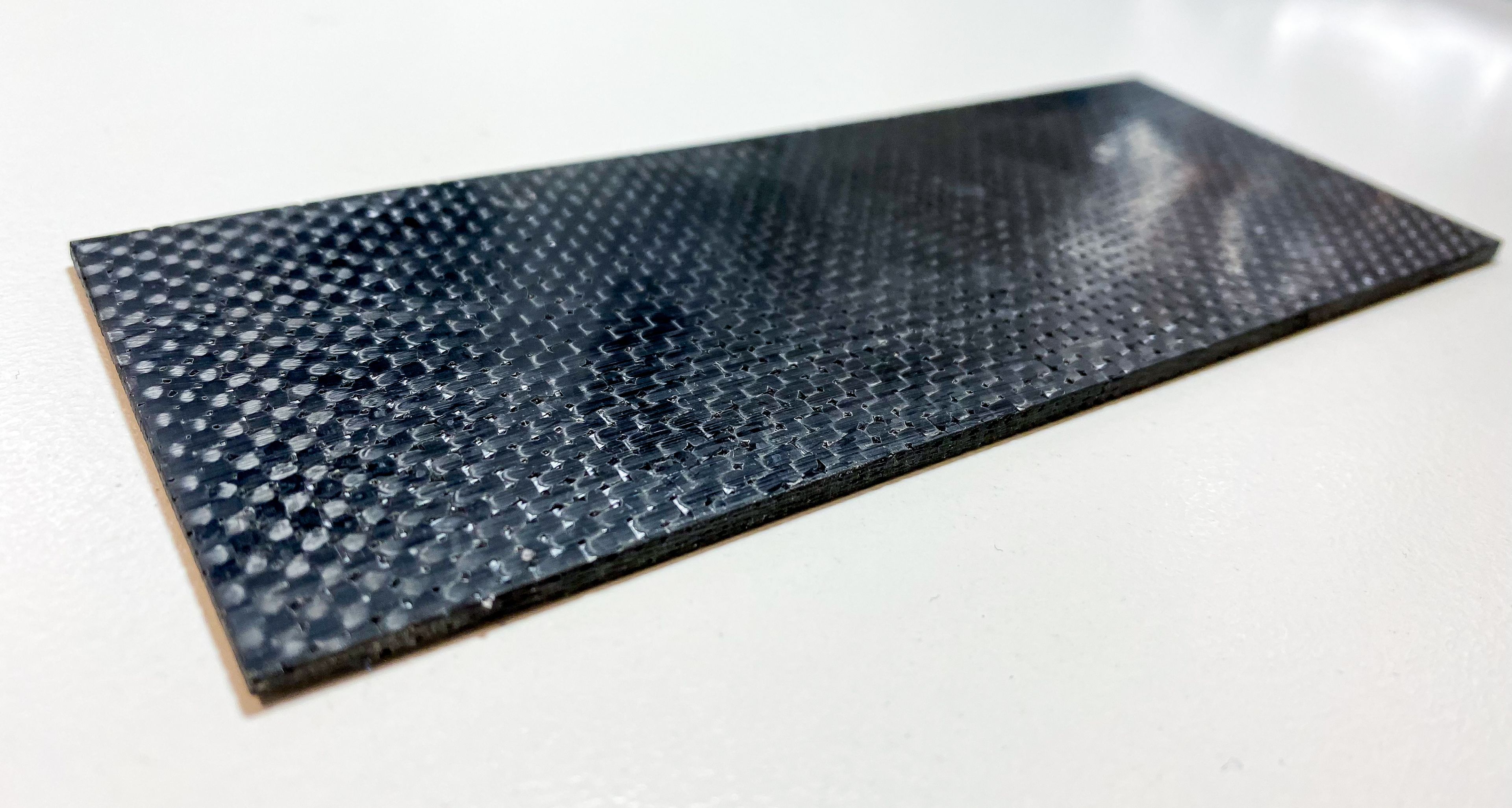

An example of the next gen composite materials being created by Swinburne researchers

Managing Director of Sparc Technologies Mike Bartels said the project was an example of the innovative solutions that could be realised through university and industry collaboration.

"Working with Swinburne University of Technology, we are pushing the boundaries of what is capable in advanced manufacturing and graphene-based technologies to truly transform industries."

Making our structures smart

Carbon fibre composites are an essential part of modern infrastructure but the physical and environmental forces they experience often cause defects that cannot be detected by visual inspection.

This project aims to use graphene-based nanomaterials to create a working prototype of a smart structure with wireless connectivity that can be remotely monitored for these difficult-to-identify defects.

This includes allowing technicians to monitor wind-turbine blades in remote mountain or coastal locations and detecting faults in airplane and rocket parts before they fail.

Lead investigator Associate Professor Nishar Hameed said the project would have important implications for safety, reliability and cost in space, aerospace and renewable energy.

"We are helping to create an interconnected network of smart composites that can transform how we build and maintain massive structures like airplanes and wind turbines," he said.

"This technology could help address the massive cost - human, economic, environmental - of catastrophic disasters like airplane crashes, while delivering benefits across a range of industries."