From a meaningless block of plastic to an advanced component that contributes to the energy transition. The technicians and scientists of our faculty think it out in detail and make it a reality. This special project shows that they need each other.

Behind the advanced experiments in the measurement halls and labs are not only scientists, but also technicians from the fine mechanical department (FMD). These technicians design and create parts for research setups across the faculty. This is also the case for Felix Smits' research to make sustainable, circular fuel a reality. To do so, he needs a special reactor chamber.

'In Leiden, the technicians really think along with the researchers, that is quite special.'

It starts with a design

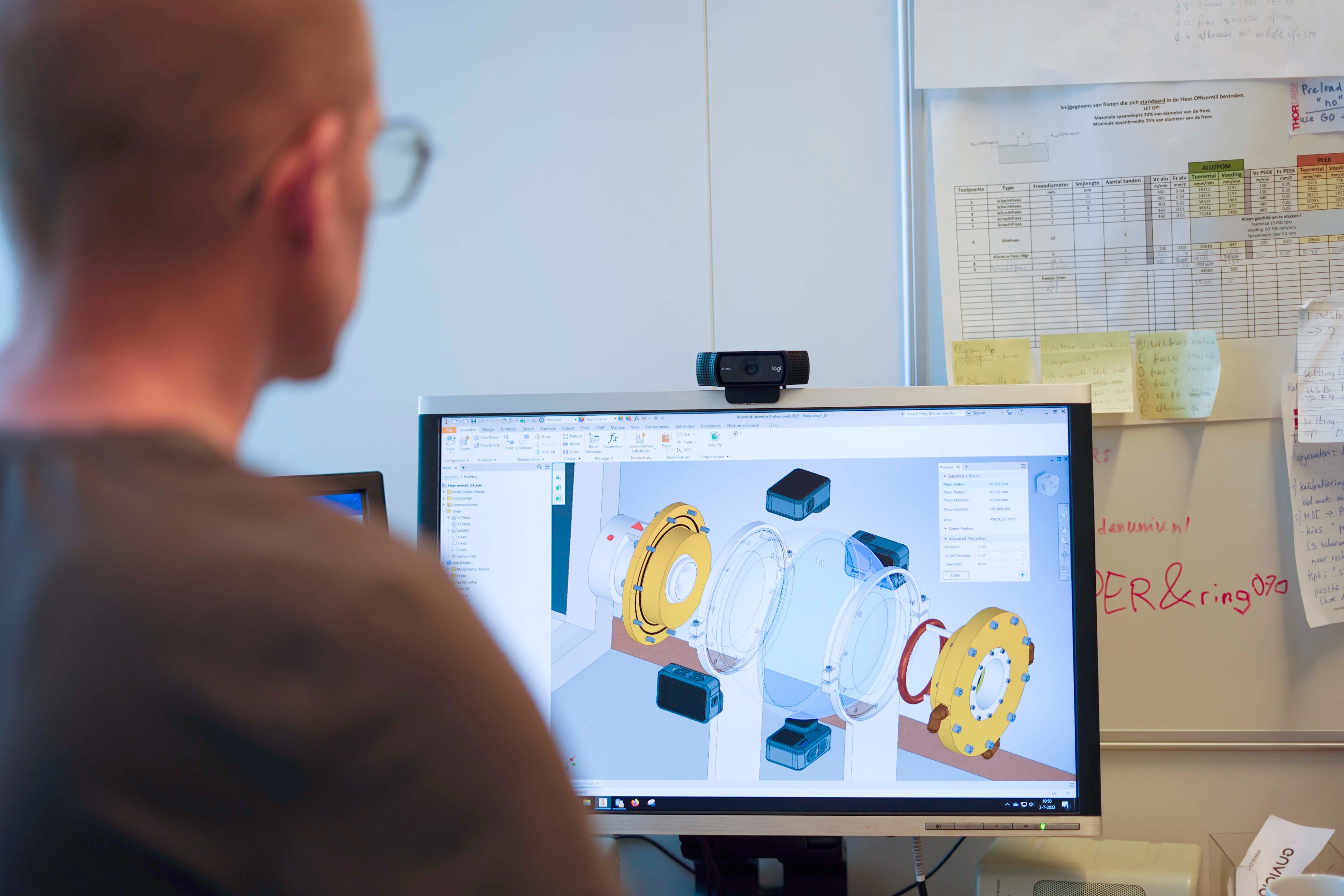

'When a researcher comes up with a new experiment, they soon knock on our door. Then we can help think about the technical requirements and the best design,' says Emiel Wiegers, FMD technician. In the reactor chamber project, Wiegers is responsible for the design. 'In consultation with Felix, I worked out the design in detail and made technical drawings. But of course, it also needs to be feasible to actually make it, and that's where Raphaël comes in.'

The production process: 'This is truly a nerve-racking job'

Raphaël Zwier often works on complex parts. And the production of the reaction chamber was definitely complex. 'The big challenge was to make the chamber transparent. The final version will be made of aluminium, but now the researchers need to be able to see the gas flows in it to see if their model is correct. Therefore, the chamber had to be made out of a transparent plastic, perspex, and that has its complications.'

Raphaël Zwier with the perspex reactor chamber he produced.

Raphaël Zwier and Emiel Wiegers at their workshop at the fine mechanical department.

Colleagues present the part.

Emiel Wiegers makes the technical drawings of the design.

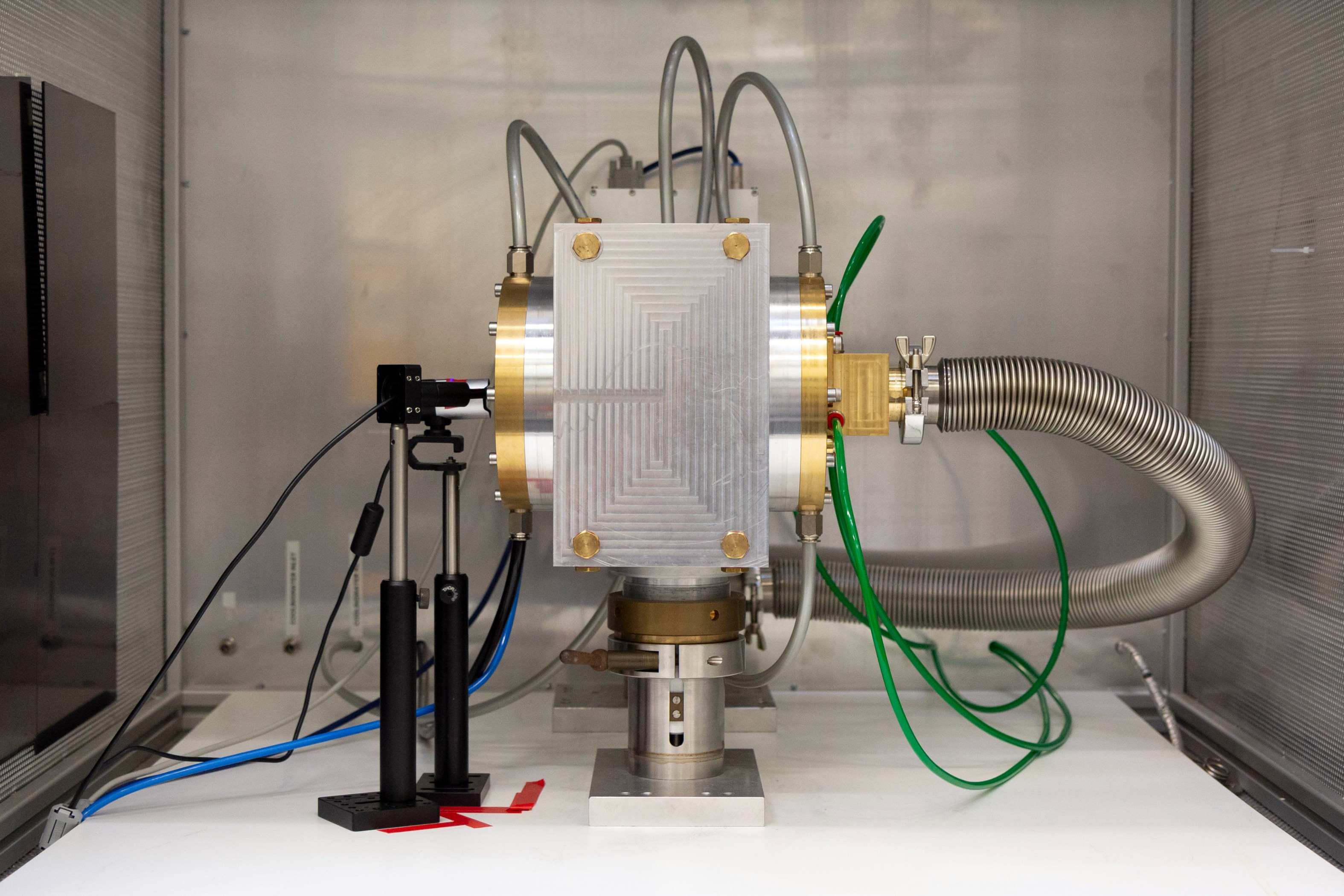

The reactor chamber in DIFFER's setup, finished in aluminium as it will be in the final version.

It starts with the fact that there aren't any big enough blocks of perspex to make the part in one piece. 'So I had to make two half-spheres,' explains Zwier. 'During machining, tensions can arise that can make the material cloudy. We solved that with heat treatments in an oven. And when you can glue the halves together, you have to avoid air bubbles in the seam.' He even had to make special tools to get the job done. 'There was no commercial chisel holder to be found to hollow out the sphere, so I made that too. With a sharp diamond chisel, I worked the perspex making the sphere transparent.'

'We are getting one step closer to solving the climate problem.'

Wiegers: 'This was truly a nerve-racking job, but Raphaël went for it. I wouldn't have done it myself. When he was working on the most difficult part, we turned down the radio and steered clear of him. Still, such big projects are great fun because of the interaction between the researcher and the makers.'

The end goal: circular fuel production

Back to physicist Smits, an expert on microwaves and plasmas. His research takes place in Dirk Bouwmeester's research group. Together with the Dutch Institute for Fundamental Energy Research (DIFFER) in Eindhoven, he is working on a new type of reactor to convert carbon dioxide (CO2) into carbon monoxide (CO): the TECH reactor. You can then use the CO to produce fuel. Smits analyses gas flows and DIFFER researchers study the required plasma, led by Waldo Bongers. Together, they are working on the reactor's microwave design. The set-ups will eventually be combined into a working prototype.

Due to the selected cookie settings, we cannot show this video here.

Watch the video on the original website or Accept cookies

Green energy alone is not the solution

Renewable energy sources such as solar and wind power are an important part of the energy transition. There is just one big problem: the wind is not always strong and the sun sets. When there is not enough green energy, gas power plants turn on and store the CO2 created in the process. Then, when there is surplus of green energy, the TECH reactor turns on and produces fuel from that CO2, making the system circular. The reactor makes it possible to store large amounts of green energy in fuel without the need for rare and expensive materials as in batteries. In other words: two birds with one stone.

Together towards a sustainable future

'We want to do something about global warming,' Smits explains his motivation for this research. 'Of course we hope that our results meet the expectations, then we can start building a prototype. We are getting one step closer to solving the climate problem.' And for that solution, good cooperation is crucial, says Wiegers: 'In Leiden, the technicians really think along with the researchers, that is quite special. Researchers consult with technicians, who then help design and come to a solution. That cooperation is incredibly important and beautiful.'