The company producing an early fault detection (EFD) system that helps prevent bushfires and blackouts globally has established a new manufacturing hub in Richmond.

IND Technology has commercialised this innovation from RMIT University and installed it across the United States and Canada, New Zealand, Malaysia and Australia.

The EFD technology acts like a smoke alarm for the power network, covering up to five kilometres of powerlines with two devices that listen to radio frequency signals travelling up and down power lines.

Some of these radio frequency signals are generated by failing assets on the powerlines. The EFD system uses the radio frequency information collected by the sensors to work out where and which equipment is failing. With the EFD system, network owners can monitor every network asset 24/7, including during extreme weather when asset failures are likely to first appear.

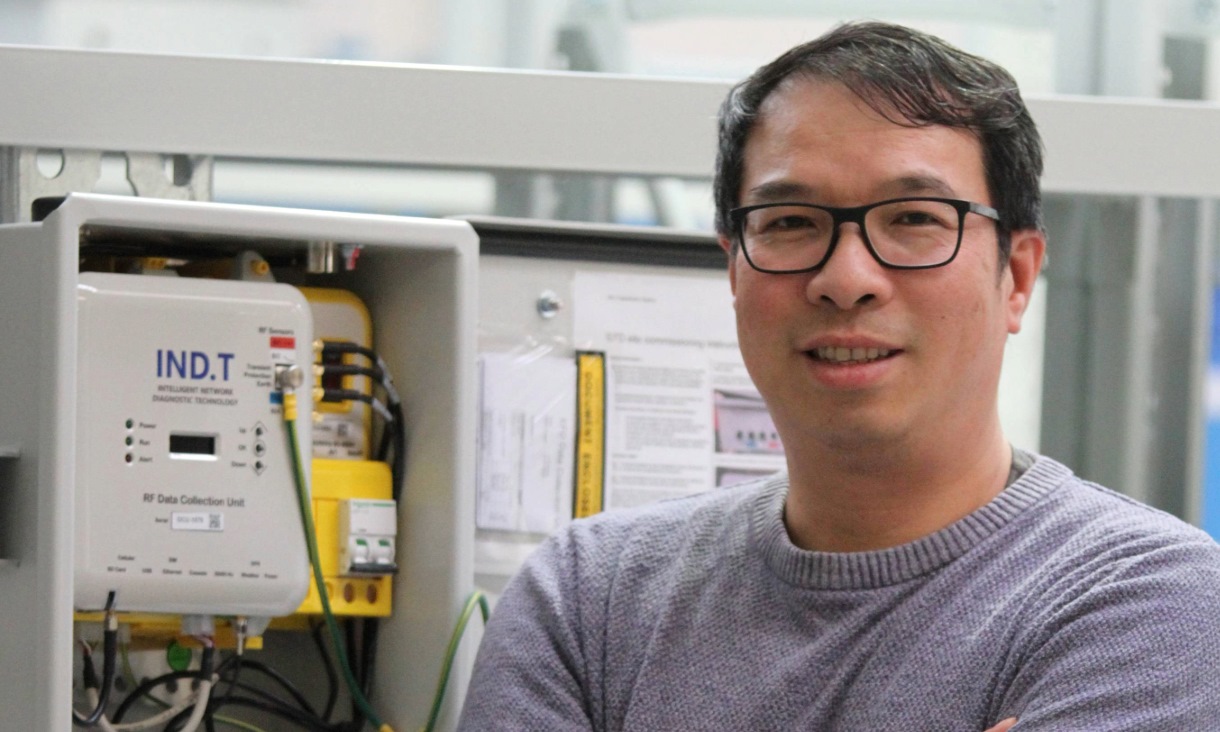

Professor Alan Wong invented the Early Fault Detection system at RMIT. Credit: supplied

Professor Alan Wong, who invented the EFD system at RMIT, is the founder and CEO of IND Technology.

He said the new facility would generate millions of dollars of export income for Victoria and Australia. The EFD system comprises parts made almost entirely in Melbourne.

An IND Technology manufacturing worker with an EFD device at a testing station within the company's new manufacturing hub in Richmond. Credit: supplied.

"We are strengthening Australia's advanced manufacturing sector, creating high-tech local jobs and showcasing homegrown innovation," Wong said.

"Our EFD systems have already prevented more than 500 potential fires, primarily in North America where it has been widely adopted.

"The demand for our product in North America has fuelled the expansion of our manufacturing facility in Melbourne. The facility will allow us to produce more than 10,000 EFD devices each year to meet the growth."

The new manufacturing facility will produce more than 10,000 EFD devices each year to meet the growth in demand globally. Credit: supplied

With this new hub, IND Technology is seeking to work closely with regulators and governments to ensure the EFD system also gets rolled out across Victoria and the rest of Australia.

In November last year, the company submitted a report to the Department of Energy, Environment and Climate Action on the FireSafe Early Fault Detection trial.

"Our trial tested this bushfire safety technology across rural Victoria," Wong said.

"A lot of Victoria's worst bushfires, like the ones on Black Saturday, were caused by faults in these old powerlines.

"These powerlines are still being used to power remote areas today, and the risk is still very real."

(L-R) Will Fowles MP, Ann-Marie Hermans MP, Tony Marxsen (Chairman of IND Technology), Professor Alan Wong, RMIT Deputy Vice-Chancellor Research and Innovation Distinguished Professor Calum Drummond AO, Richard Riordan MP and Ashley Hunt (Director of Cladding Safety Victoria) at the launch event of the new facility. Credit: supplied

Distinguished Professor Calum Drummond AO, Deputy Vice-Chancellor Research and Innovation and Vice-President at RMIT University, said IND Technology's trajectory exemplified the university's mission to translate academic research for societal benefit.

"IND Technology is on a strong growth trajectory selling 60 devices in 2020 and 4,000 in 2024," he said.

"Not only has this meant local job and wealth creation, it has also meant lives and property are being saved through the translation and roll-out of this technology born at RMIT."