For the first time, ETH materials scientists are measuring the rolling friction of tiny, micrometre-sized particles. These measurements permit them to better understand everyday products such as concrete.

In brief

- ETH materials scientists are the first to measure the microscopic forces involved when particles in suspensions such as concrete or paint roll past each other.

- Previously, such measurements could only be carried out on a macroscopic scale.

- The researchers derived friction coefficients from the measurements, which are now being incorporated into computer models to simulate suspensions.

Lacquers, paint, concrete-and even ketchup or orange juice: Suspensions are widespread in industry and everyday life. By a suspension, materials scientists mean a liquid in which tiny, insoluble solid particles are evenly distributed. If the concentration of particles in such a mixture is very high, phenomena can be observed that contradict our everyday understanding of a liquid. For example, these so-called non-Newtonian fluids suddenly become more viscous when a strong force acts upon them. For a brief moment, the liquid behaves like a solid.

This sudden thickening is caused by the particles present in the suspension. If the suspension is deformed, the particles have to rearrange themselves. From an energy perspective, it is more advantageous if they roll past each other whenever possible. It is only when this is no longer possible, e.g. because several particles become jammed, that they have to slide relative to each other. However, sliding requires much more force and thus the liquid feels macroscopically more viscous.

The interactions that occur on a microscopically small scale therefore affect the entire system and they determine how a suspension flows. To optimise the suspension and specifically influence its flow characteristics, scientists must therefore understand the magnitude of the frictional forces between the individual particles.

What did the scientists investigate?

ETH materials researchers led by Lucio Isa, Professor of Interfaces and Soft Matter, developed a method of measuring the frictional forces between individual particles only a few micrometres in diameter.

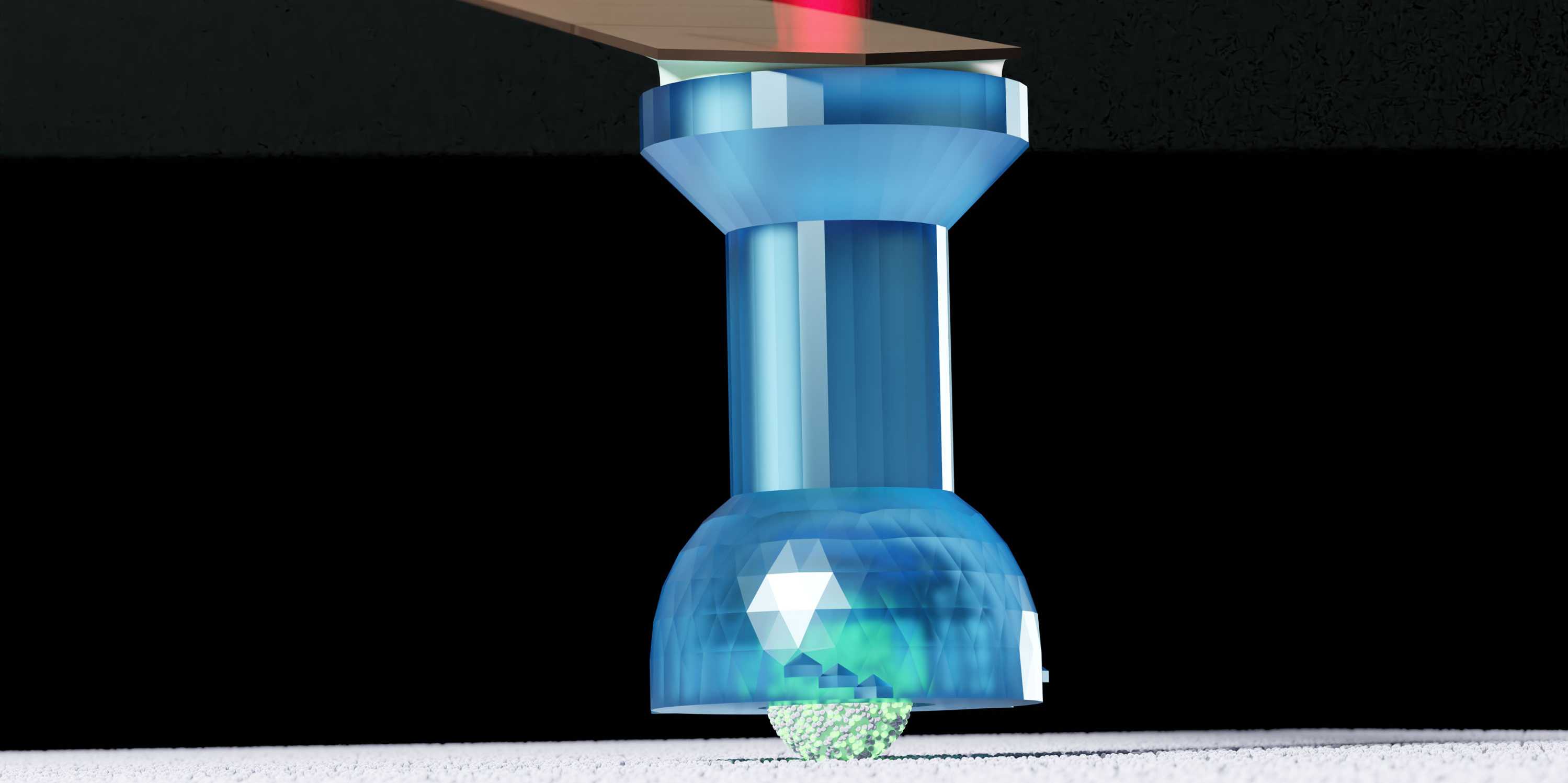

The researchers used a so-called atomic force microscope for their measurements. Doctoral student Simon Scherrer first developed a microscopically small holder, which serves to capture one single spherical particle. Then they move this "trapped" particle over a flat surface with the same characteristics as the particle, using the atomic force microscope. In this way, the researchers were able to imitate two particles moving past each other and measure the tiny forces between the surfaces.

Why is this so crucial?

The particles examined are tiny - a mere 12 micrometres, i.e. 12 millionths of a metre, in diameter. It was correspondingly difficult to develop a suitable measurement technique to measure the rolling friction occurring on the particle. Making a suitable holder proved to be particularly challenging. "I must have developed 50 versions until I found one that met the requirements", Scherrer reveals.

The researchers made different particles in order to understand how the surface of the tiny particles affects the behaviour of the suspension. "Particles with a smooth or very slippery surface simply slid past each other regardless of how firmly we pressed them together", Scherrer explains.

The situation with rough or sticky particles was very different, as these particles engage with each other like gearwheels and they roll with little resistance. Lastly, the researchers fixed the particles in the holder in order to measure their sliding friction. This friction is many times higher than the rolling friction and it explains the dramatic thickening of the suspensions.

What purpose does this serve?

The researchers were able to derive the coefficients for the rolling and sliding friction of the respective particles directly from their measurements. These figures can be used in computer models to simulate suspensions with a high fraction of particles, for example, and thereby to determine the optimum flow characteristics. These insights into the microscopic mechanisms that are the root cause of the thickening are opening up new approaches for optimising suspensions for applications in industry, construction or everyday life.

Among others, the beneficiaries might include the concrete industry or microelectronics manufacturers. The latter are already using dense suspensions with metallic, conductive particles in order to solder components to circuit boards. The solder paste is pressed through narrow nozzles. If the pressure is too great, the paste can suddenly thicken and clog up the nozzle.

"In order to prevent this behaviour and optimise such suspensions, we have to know precisely how particles behave on a microscale and what forces occur in the process", Isa says.

References

Scherrer S, Ramakrishna SN, Niggel V, Hsu C-P, Style RW, Spencer ND, Isa, L. Characterizing sliding and rolling contacts between single particles, PNAS March 6, 2025122 (10) e2411414122 external page DOI: external page 10.1073/pnas.2411414122