Abstract

With the advent of the Metaverse era, there have been growing expectations that virtual reality (VR) and augmented reality (AR) technologies will likely to enhance convenience in everyday life, as well as industry productivity performance.

A joint research team, affiliated with UNIST has introduced core technology for smart contact lenses that can implement AR-based navigation through a 3D printing process. According to the research team, the new smart contact lenses can be worn inside the eye of a person, like a normal contact lens.

Published in the February 2023 issue of Advanced Science, this breakthrough has been jointly led by Professor Im Doo Jung in the Department of Mechanical Engineering at UNIST and Dr. Seung Kwon Seol from the Smart 3D Printing Research Team at Korea Electrotechnology Research Institute (KERI).

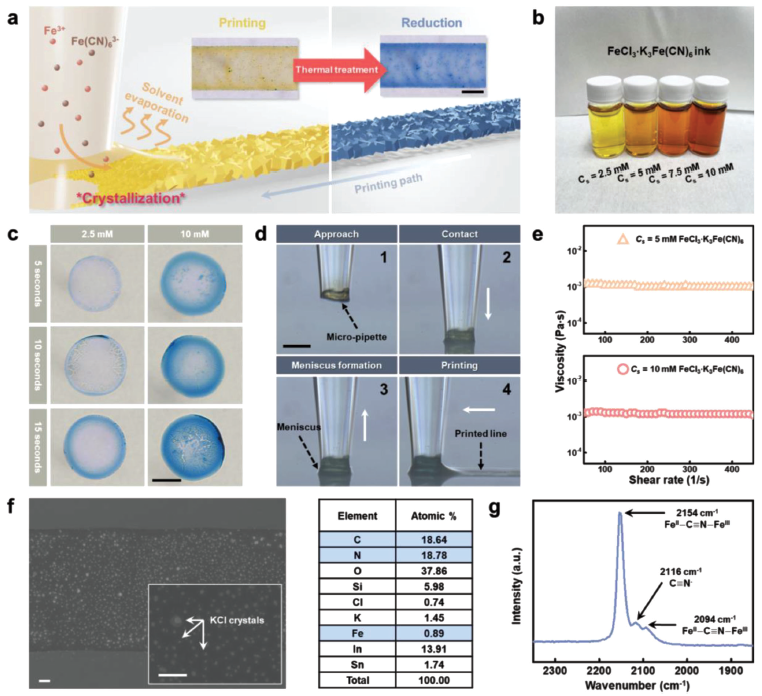

Figure 1. Meniscus-guided micro-printing of Prussian blue (PB).

Some of the disadvantages of existing AR devices include high price, experimental technology, and bulky appearance, making them difficult to get access to the market. Smart contact lenses, on the other hand, have the advantages of being affordable and convenient, as it can be worn inside the eye of a person. Leading companies throughout the world, such as Google are currently working on creating smart contact lenses, capable of implementing AR. Still, there exists barriers that impede the effective and efficient commercialization of research due to severe technical challenges.

In implementing AR with smart contact lenses, energy-saving electrochromic (EC) displays that can be driven with low power are suitable. Prussian blue (PB) has been regarded as one of the attractive EC material due to its uniform coloration, fast kinetics, high optical contrast, multiple color states (blue, white, green), environmental friendliness, and cost competitiveness. However, this method has limitations in displaying words or images that are needed for a display on AR smart contact lenses because of the difficulty of micro-patterning PB on the contact lens, noted the research team.

The joint research team worked on ways not to use an electroplating process, and as a result, they developed simple and effective printing strategy to produce micro-patterns of PB using the meniscus-guided printing of an acidic-ferric-ferricyanide ink composed of FeCl3, K3Fe(CN)6, and HCl.

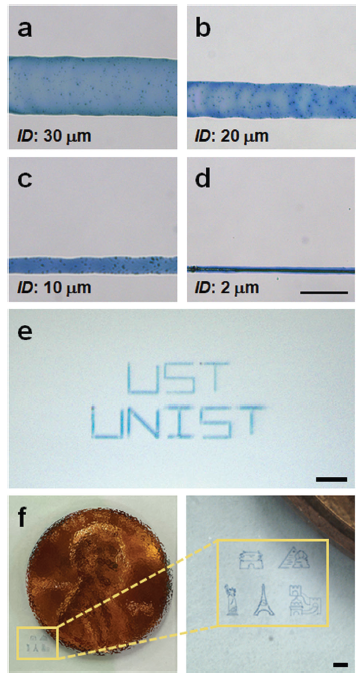

Figure 2. Optical micrographs presenting the dependence of the printed line width on inner diameter (ID).

Meniscus is a phenomenon in which water droplets form concave curved surfaces on the outer wall due to surface tension in the capillary tube. The meniscus formed between the nozzle and the substrate is crystallized by evaporating the solvent therein. With conventional electroplating methods, the substrate must be a conductor to apply a voltage. However, using the meniscus phenomenon, crystallization proceeds due to natural evaporation of solvents, so there is no restriction on substrates. The research team's micro-pattern technology can form patterns on curved surfaces as well as flat surfaces. It is also very fine (7.2 micrometers) that can be applied to smart contact lens displays for AR, and the color is continuous and uniform.

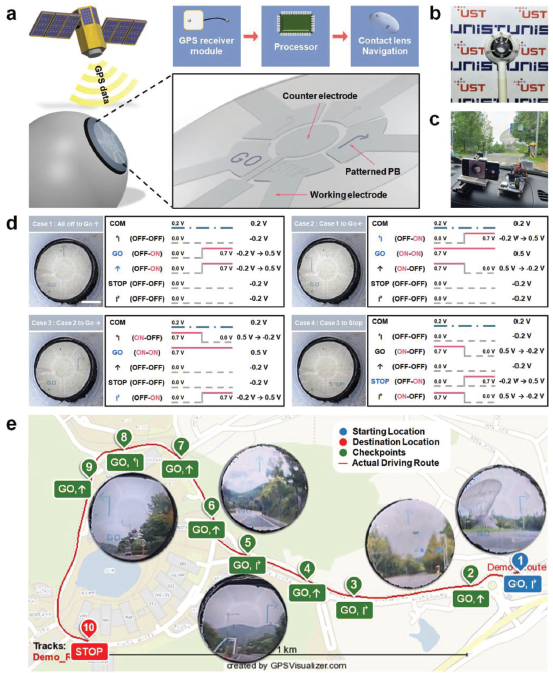

The main expected application area is navigation. The researchers implemented AR so that navigation can unfold in front of people's eyes so that users can find their way in real time by combining an electrochromic display with contact lenses. Just by wearing a lens, the navigation system unfolds in front of human eyes through AR.

Figure 3. Electrochromic (EC) display for navigation system embedded in a contact lens.

"Our achievement is a 3D printing technology that can print functional micro-patterns on non-planner substrate that can commercialize advanced smart contact lenses to implement AR," noted the research team. "It will greatly contribute to the miniaturization and versatility of AR devices."

In recognition of its excellence, the related research results have been featured as the back cover of Advanced Science (IF 17.521/JCR 4.71%), a world-renowned academic journal in the field of materials science.

Journal Reference

Je Hyeong Kim, Seobin Park, Jinhyuck Ahn, et al., "Meniscus-Guided Micro-Printing of Prussian Blue for Smart Electrochromic Display," Advanced Science (2023).