Abstract

A novel technology for real-time monitoring of tool wear in precision machining has been developed, utilizing smartphone sensors. This advancement is expected to enhance the quality of production by enabling proactive maintenance and timely tool replacement.

A joint research team, led by Professor Chung Wook Park from the Department of Mechanical Engineering and Professor Sunghoon Lim from the Graduate School of Industrial Engineering and Artificial Intelligence at UNIST has created a method for real-time tool wear prediction. This innovative approach aims to facilitate the timely replacement of cutting tools, optimizing production efficiency.

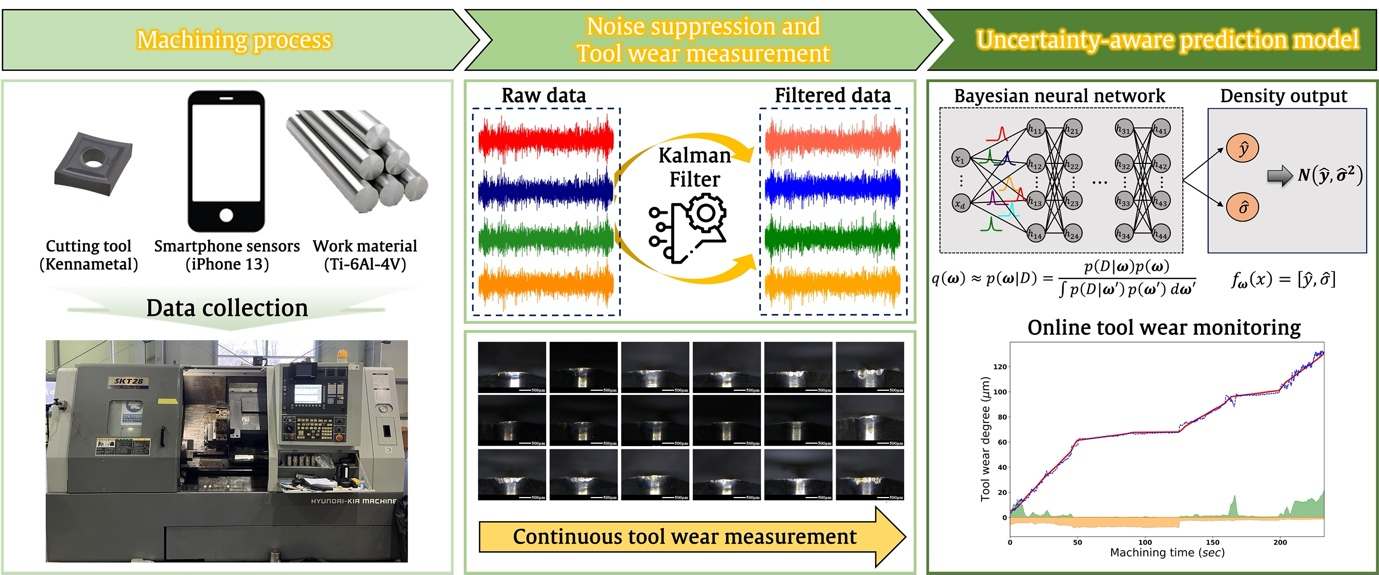

Figure 1. An overview of the proposed uncertainty-aware tool wear prediction method.

In this study, the team introduced a deep learning-based predictive model that incorporates filtering techniques to mitigate data noise and account for uncertainties encountered during processing. This method significantly enhances both the performance and reliability of tool wear predictions while improving accuracy compared to previous research endeavors.

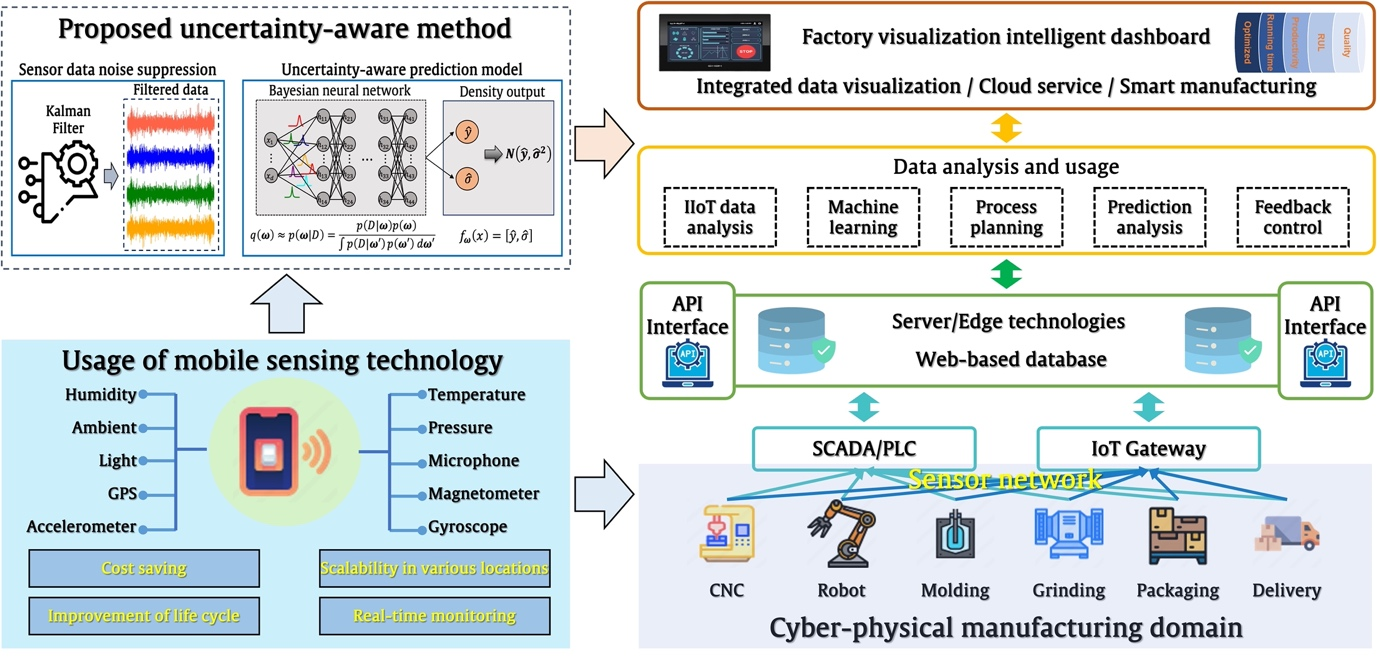

Figure 2. A cyber manufacturing system framework using mobile sensing and the proposed method.

Titanium alloy (Ti-6Al-4V), prevalent in high-tech manufacturing sectors, such as aerospace and biomedical fields, poses challenges due to rapid tool wear resulting from its poor thermal properties. Consequently, there is a critical need for real-time monitoring of tool conditions.

"We have achieved a higher level of accuracy in tool wear prediction by minimizing noise within smartphone sensor data and leveraging advanced deep learning techniques," stated Gyeongho Kim in the Department of Industrial Engineering at UNIST. Sang Min Yang in the Department of Mechanical Engineering at UNIST further emphasized, "This development will greatly contribute to the advancement of efficient and cost-effective production and manufacturing systems, as it allows for real-time predictions via a smartphone application, eliminating the need for expensive sensors."

The findings of this research will be published in the Journal of Manufacturing Systems, a leading international journal in the fields of production, manufacturing, and industrial engineering. The study received support from the National Research Foundation of Korea (NRF), the Institute of Information & communications Technology Planning & Evaluation (IITP), the Ministry of Trade, Industry and Energy (MOTIE), and the AI Challengers Program (AICP) of UNIST.

Journal Reference

Gyeongho Kim, Sang Min Yang, Dong Min Kim, et al., "Developing a deep learning-based uncertainty-aware tool wear prediction method using smartphone sensors for the turning process of Ti-6Al-4V," J. Manuf. Syst., (2024).