Scientists at Oxford University Physics Department have developed a revolutionary approach which could generate increasing amounts of solar electricity without the need for silicon-based solar panels. Instead, their innovation works by coating a new power-generating material onto the surfaces of everyday objects such as rucksacks, cars, and mobile phones.

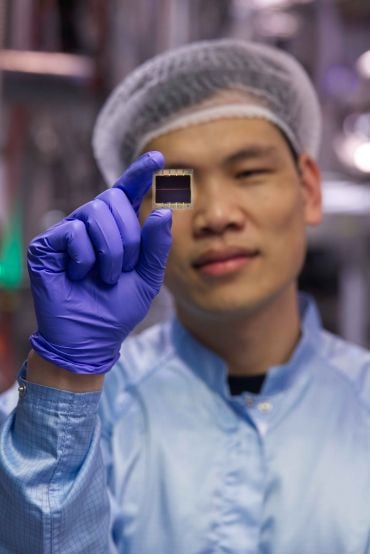

Dr Shuaifeng Hu, Post Doctoral Fellow at Oxford University Physics, examining the new thin-film perovskite material. Image credit: Martin Small.

Dr Shuaifeng Hu, Post Doctoral Fellow at Oxford University Physics, examining the new thin-film perovskite material. Image credit: Martin Small.Their new light-absorbing material is, for the first time, thin and flexible enough to apply to the surface of almost any building or common object. Using a pioneering technique developed in Oxford, which stacks multiple light-absorbing layers into one solar cell, they have harnessed a wider range of the light spectrum, allowing more power to be generated from the same amount of sunlight.

This ultra-thin material, using this so-called multi-junction approach, has now been independently certified to deliver over 27% energy efficiency, for the first time matching the performance of traditional, single-layer, energy-generating materials known as silicon photovoltaics. Japan's National Institute of Advanced Industrial Science and Technology (AIST), gave its certification prior to publication of the researchers' scientific study later this year.

'During just five years experimenting with our stacking or multi-junction approach we have raised power conversion efficiency from around 6% to over 27%, close to the limits of what single-layer photovoltaics can achieve today,' said Dr Shuaifeng Hu, Post Doctoral Fellow at Oxford University Physics. 'We believe that, over time, this approach could enable the photovoltaic devices to achieve far greater efficiencies, exceeding 45%.'

This compares with around 22% energy efficiency from solar panels today (meaning they convert around 22% of the energy in sunlight), but the versatility of the new ultra-thin and flexible material is also key. At just over one micron thick, it is almost 150 times thinner than a silicon wafer. Unlike existing photovoltaics, generally applied to silicon panels, this can be applied to almost any surface.

'By using new materials which can be applied as a coating, we've shown we can replicate and out-perform silicon whilst also gaining flexibility. This is important because it promises more solar power without the need for so many silicon-based panels or specially-built solar farms,' said Dr Junke Wang, Marie Skłodowska Curie Actions Postdoc Fellow at Oxford University Physics.

The latest innovations in solar materials and techniques demonstrated in our labs could become a platform for a new industry, manufacturing materials to generate solar energy more sustainably and cheaply by using existing buildings, vehicles, and objects.

Henry Snaith, Professor of Renewable Energy, Oxford University Physics Department.

The researchers believe their approach will continue to reduce the cost of solar and also make it the most sustainable form of renewable energy. Since 2010, the global average cost of solar electricity has fallen by almost 90%, making it almost a third cheaper than that generated from fossil fuels. Innovations promise additional cost savings as new materials, like thin-film perovskite, reduce the need for silicon panels and purpose-built solar farms.

'We can envisage perovskite coatings being applied to broader types of surface to generate cheap solar power, such as the roof of cars and buildings and even the backs of mobile phones. If more solar energy can be generated in this way, we can foresee less need in the longer term to use silicon panels or build more and more solar farms' Dr Wang added.

The researchers are among 40 scientists working on photovoltaics led by Professor of Renewable Energy Henry Snaith at Oxford University Physics Department. Their pioneering work in photovoltaics and especially the use of thin-film perovskite began around a decade ago and benefits from a bespoke, robotic laboratory.

Henry Snaith, Professor of Renewable Energy, at Oxford University Physics Department. Image credit: Martin Small.

Henry Snaith, Professor of Renewable Energy, at Oxford University Physics Department. Image credit: Martin Small.Their work has strong commercial potential and has already started to feed through into applications across the utilities, construction, and car manufacturing industries.

Oxford PV, a UK company spun out of Oxford University Physics in 2010 by co-founder and chief scientific officer Professor Henry Snaith to commercialise perovskite photovoltaics, recently started large-scale manufacturing of perovskite photovoltaics at its factory in Brandenburg-an-der-Havel, near Berlin, Germany. This is the world's first volume manufacturing line for 'perovskite-on-silicon' tandem solar cells.

'We originally looked at UK sites to start manufacturing but the government has yet to match the fiscal and commercial incentives on offer in other parts of Europe and the United States,' Professor Snaith said. 'Thus far the UK has thought about solar energy purely in terms of building new solar farms, but the real growth will come from commercialising innovations - we very much hope that the newly-created British Energy will direct its attention to this.'

'Supplying these materials will be a fast-growth new industry in the global green economy and we have shown that the UK is innovating and leading the way scientifically. However, without new incentives and a better pathway to convert this innovation into manufacturing the UK will miss the opportunity to lead this new global industry,' Professor Snaith added.