The Design Sprint brought together industry and academia partners to improve the process for maintenance of brake pads on the B-52H Stratofortress.

The 2nd Maintenance Squadron, or 2MXS, which produces an average of 20 to 25 brakes per month for B-52s at Barksdale Air Force Base, Louisiana and Minot AFB, North Dakota is tasked with accurately drilling 96 individual pucks out of five stators/pressure plates. According to the Airmen of the 2MXS, the drilling of these pucks is done in specific spots, to a specific depth and all by eye, which can lead to costly damage to the plates.

Tech. Sgt. Nicholas Geiger, 2MXS section chief for bomber hydraulics at Barksdale AFB, estimates a loss of $106,000 each year due to damaged plates from miss-drilling, plus countless lost man hours from a labor-intensive process.

"This was a problem long before me, so our leadership was able to bring it to STRIKEWERX's attention, and I think it was an amazing event. We could have used something like this 10 years ago," Geiger said. "I am excited to see the prototype in action. This is a great tool to teach the Airmen how to drill the brakes correctly and speed up the process while also making it safer for the Airmen to do their job."

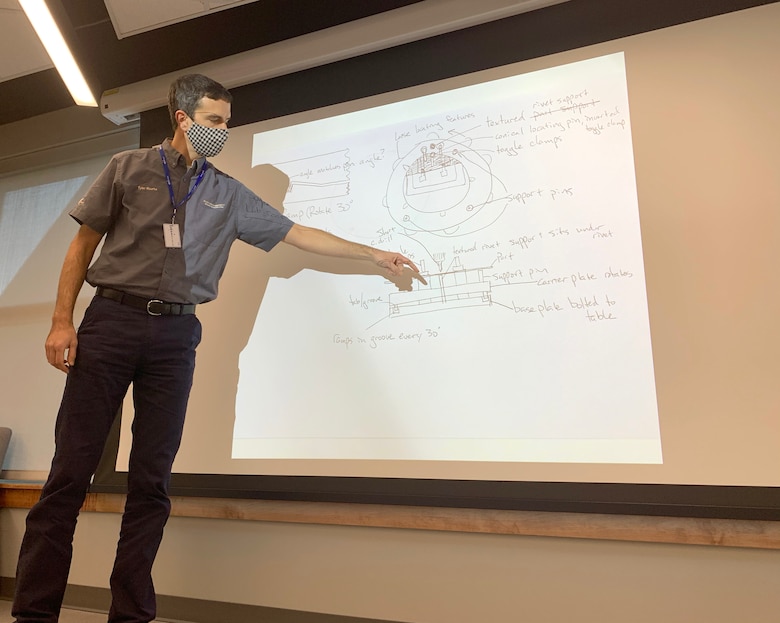

The Design Sprint team produced two prototypes designed by Electroimpact, of Mukilteo, Washington and Louisiana Tech University, and 3D printed at LSU Shreveport's Cyber Collaboratory. They were then tested at Barksdale AFB's maintenance shop.

"The problem seems small at first, a single backshop within the 2MXS spending 80 hours per month drilling, but when you look at how this one shop touches B-52 brakes across the command and it's clear that this is a major issue that we can solve with our innovative approaches," said Maj. Ryan Chapman, AFGSC executive chief scientist. "This team of manufacturing experts across industry and academia moved quickly to develop a solution and invest in making our Airmen's ideas a reality."

The event exemplified how STRIKEWERX helps solve challenges faced by AFGSC in a quick, efficient way.

"Our second design sprint was a huge success in solving a complicated issue for the command's aircraft maintainers," said Russ Mathers, STRIKEWERX director. "Airmen who know the process and are performing the work were able to come in, work with academia and industrial experts, and see their idea not only supported, but realized by AFGSC headquarters."

STRIKEWERX will continue to host Design Sprints to tackle various issues from around the command.

"If you are an Airman out there with an innovative idea, we want to know about it," Chapman said. "Your idea could be the next Design Sprint. You can have a team of industry and academia making your vision a reality to solve AFGSC's issues and improve our lethality and readiness."

Airmen and academia partners from Louisiana Tech University and LSU Shreveport work on refining a prototype design to solve drilling of B-52H Stratofortress brakes during a Design Sprint held at STRIKEWERX in Bossier City, La., Nov. 16-19, 2020. The Design Sprint brought together industry and academia partners to improve the process for maintenance of brake pads on the B-52H. (Courtesy photo)

Tyler Rourke with Electroimpact, out of Washington state, showcases a sketch of his prototype to solve drilling B-52H Stratofortress brakes during a Design Sprint held at STRIKEWERX in Bossier City, La., Nov. 16-19, 2020. The Design Sprint brought together industry and academia partners to improve the process for maintenance of brake pads on the B-52H. (Courtesy photo)