Not all plastics are equal - some types and colors are easier to recycle than others. Black foam and black coffee lids, which are often made of polystyrene, usually end up in landfills because color additives lead to ineffective sorting. Now, researchers report the ability to leverage one additive in black plastics, with the help of sunlight or white LEDs, to convert black and colored polystyrene waste into reusable starting materials.

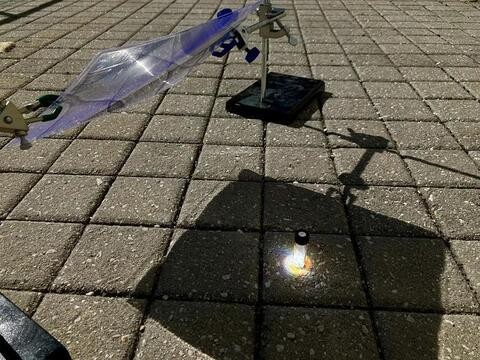

Inside this reaction vial, spotlit by concentrated sunlight, a piece of black polystyrene from a foam tray breaks down into a recyclable material.

"Simple, visible light irradiation holds the potential to transform the chemical recycling of plastics, using the additives already found in many commercial products," say the paper's authors, Sewon Oh, doctoral candidate in chemistry and chemical biology; Liat Kugelmass, M.S. '21, Ph.D. '23; and corresponding author Erin Stache and Hanning Jiang, both at Princeton.

Their paper, "Recycling of Post-Consumer Waste Polystyrene Using Commercial Plastic Additives," published Nov. 25 in ACS Central Science.

An emerging strategy for plastic recycling involves using light to help break down plastic into chemically useful materials that can be recycled into new products. This process requires a helper compound to convert light into the heat needed to break apart polymer bonds. However, finding the right helper that won't create more waste and is easily incorporated into recycled materials remains a challenge for researchers. Seeking to create a circular economy for plastic recycling, the team of researchers took advantage of something already found in black polystyrene waste - an additive known as carbon black.

Read the full story on the College of Arts and Sciences website.