Building on their groundbreaking work on the first-ever supranano magnesium alloy, a research team led by City University of Hong Kong (CityUHK) has demonstrated how supranano engineering can lead to higher strength and higher ductility in bulk structural materials.

The findings have been published in Science under the title, "Ductilization of 2.6-GPa alloys via short-range ordered interfaces and supranano precipitates". The team's work on magnesium alloys was featured on the cover of Nature in the 4 May 2017 issue.

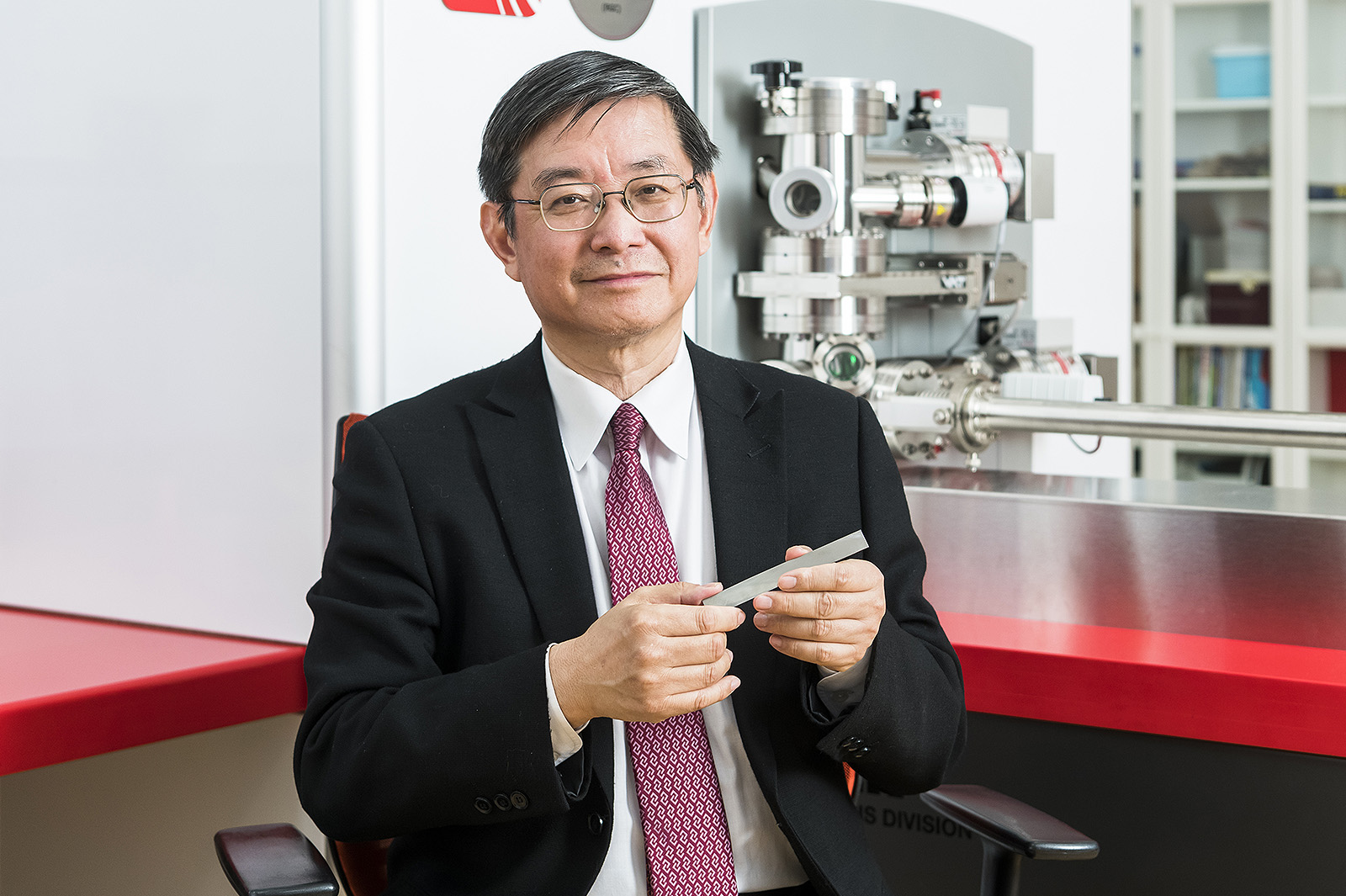

The ultimate problem that the CityUHK-led team has set out to solve is related to the strength and ductility for materials made from metals, for example, steel or titanium, said Professor Lu Jian, Dean of CityUHK's College of Engineering.

"If we want to create stronger and more ductile materials, we need to guard against producing alloys that inevitably show decreased strain-hardening capacity over time," Professor Lu said.

The unique approach adopted by Professor Lu's team is successfully controlling the arrangement and design of the grain interiors and boundaries of a fine-grained alloy at the supranano level, i.e. below 10 nanometers.

"We have previously worked on magnesium alloys but for this project, we used a multicomponent blend of metals for synthesis," Professor Lu explained, adding the three collaborative research groups under his team include his former PhD students and postdocs conducting research on supra-nano-dual-phase structures. They are now professors and research leaders at Xi'an Jiaotong University.

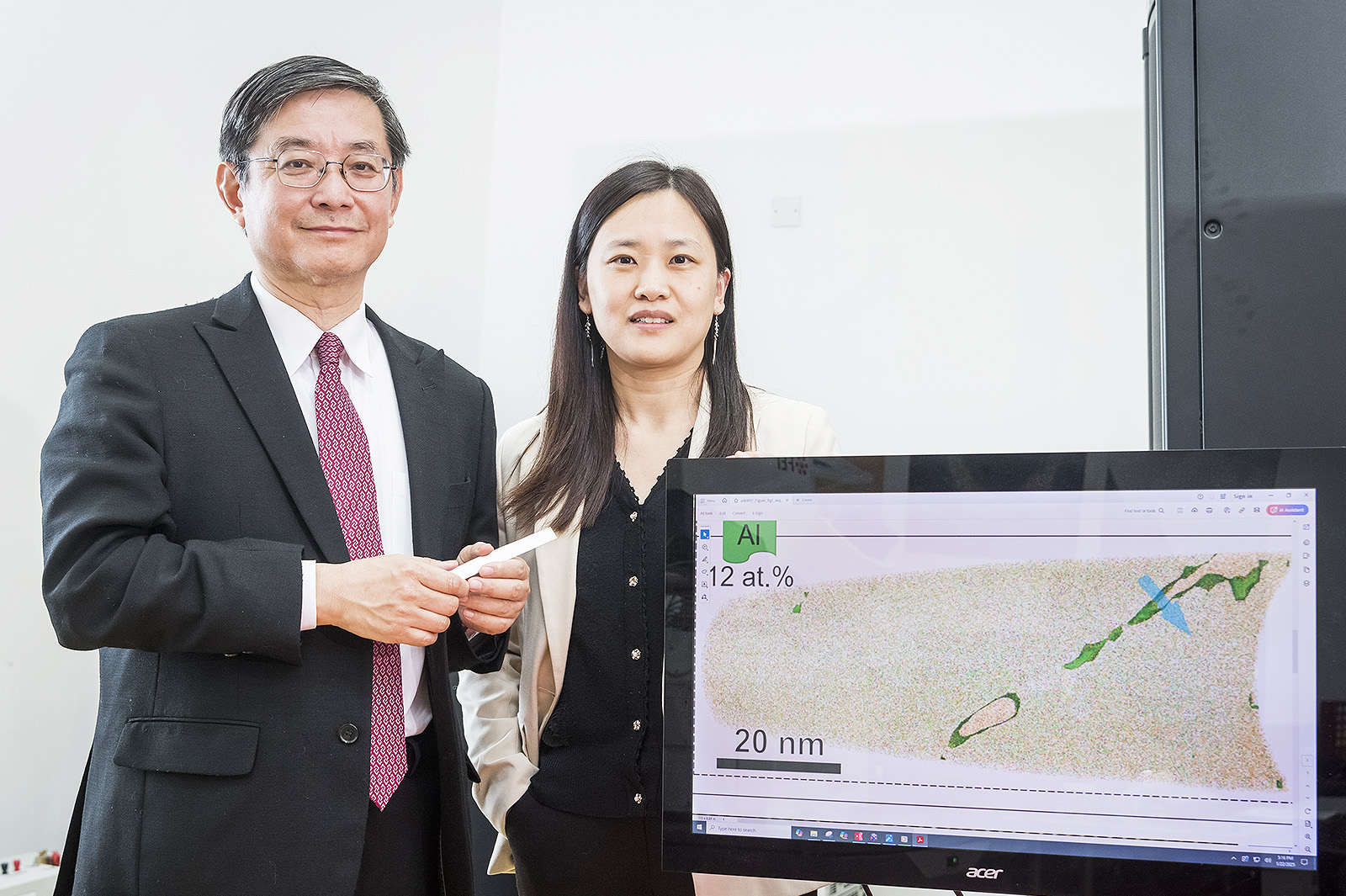

They discovered that the supranano ordering helped to promote a continuously increased flow stress until the fracture of the alloy at a remarkable 10% strain with an equally impressive 2.6-gigapascal (GPa) tensile stress.

"The yield strength of nanostructured fine-grained alloys is usually less than 1.5 to 2 GPa," he said.

Essentially, Professor Lu continues, the CityUHK-led team found that supranano orderings have a stronger pinning effect for dislocations and stacking faults (SFs). It makes the motion of dislocations and SFs slow, which increases the possibility of their interaction and entanglement with other moveable dislocations, and which promotes multiplication and accumulation of these defects upon loading.

"The supranano orderings with precipitates are uniformly distributed in the grain interior, and thus, the distribution of the generated defects is also uniform, which alleviates strain localisation, leading to mutually complementary strengthening and ductilisation and facilitating a high strain-hardening rate and large elongation," Professor Lu said.

Fine-tuning these supranano engineering techniques will further enhance the strength and ductility of different materials, leading to a spectrum of applications in aerospace, automobile, 3C (computer, communication and consumer electronics) industries, and in construction using super-strong alloys.

The project was supported by the National Natural Science Foundation of China/RGC (Research Grants Council) Joint Research Scheme, and National Natural Science Foundation of China.