Key Takeaways

- Scientists have developed a new fabrication technique that could improve noise robustness in superconducting qubits.

- The chemical etching process enables advanced flexibility and control over the design of superconducting circuits with nanosized 3D structures.

- The approach can be easily incorporated into manufacturing processes for superconducting microchips or components for qubits.

A research team led by scientists at Lawrence Berkeley National Laboratory (Berkeley Lab) has developed a new fabrication technique that could improve noise robustness in superconducting qubits, a key technology to enabling large-scale quantum computers.

The work is part of the Quantum Systems Accelerator (QSA) led by Berkeley Lab. QSA is a National Quantum Information Science (QIS) Research Center funded by the U.S. Department of Energy (DOE) Advanced Scientific Computing Research (ASCR) program. It develops quantum technologies that can potentially solve longstanding challenges in physics, chemistry, materials, and biology that can't be addressed with classical computers.

QSA brings together 15 member institutions in North America, including Sandia National Laboratories as lead partner and works on major qubit technologies.

Quantum computers could speed up R&D across sectors by solving certain complex problems exponentially faster than a classical computer. In order to make a commercial-ready quantum computer, researchers have been interested in developing a particular type of qubit - the fundamental unit of information in a quantum computer - by using materials that conduct electrical current without loss. These superconducting qubits are typically fabricated by depositing a superconducting metal onto silicon, a material that is compatible with existing microchip manufacturing techniques.

"Knowing how to make noise-resistant qubits will allow us to advance more efficient quantum computers directed at solving the scientific problems that are key to the Department of Energy's mission."

- Bert de Jong, Quantum Systems Accelerator director.

But superconducting qubits - like all qubits - are particularly susceptible to errors caused by environmental disturbances such as unwanted electric charges from materials in the device.

The new fabrication technique - which the Berkeley Lab-led team recently published in the journal Applied Physics Letters - has the potential to significantly lower noise caused by imperfection of the materials - and thereby improve performance - in superconducting qubits by lifting a circuit component called a "superinductor" from a silicon substrate. Partially suspending the superinductor in the air minimizes contact with the substrate and could therefore eliminate a significant source of noise that can compromise computing performance.

"Reducing noise induced by defects in qubits is a goal that scientists around the world have been chasing for decades. It's a challenging problem to solve. But we think that our fabrication technique - a simple chemical etching approach - could be the missing ingredient for anyone who makes superconducting microchips or components for qubits," said study co-author David I. Santiago, who leads the Quantum Information Science & Technology (QuIST) group in Berkeley Lab's Computational Research Division.

In microelectronics, tiny magnetic wires called inductors supply energy to a circuit by keeping current flowing even when a transistor is switched off. Similarly, superinductors may allow superconducting qubits to flow charge more continuously - and this continuous flow of electricity could make them more robust against noise channels.

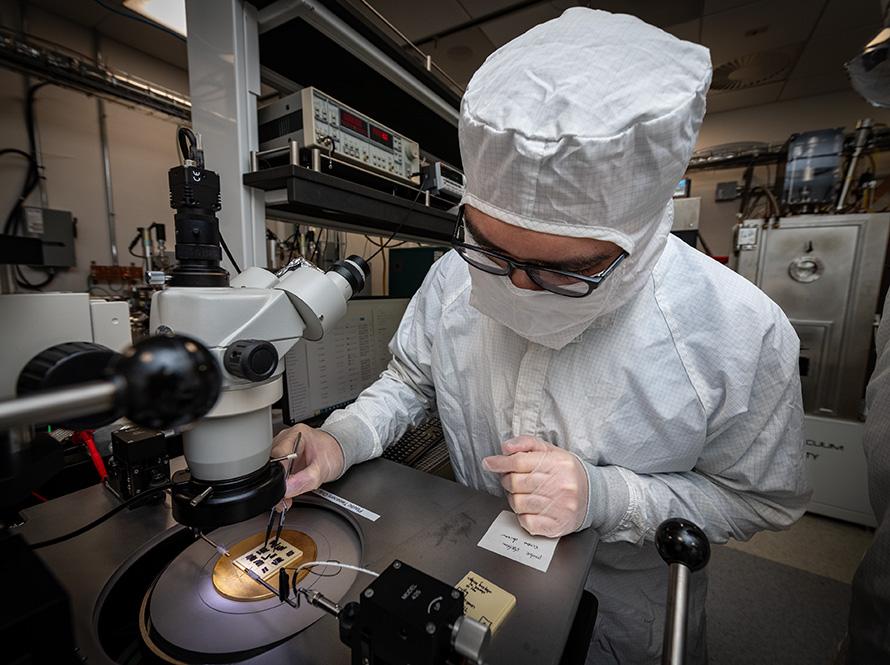

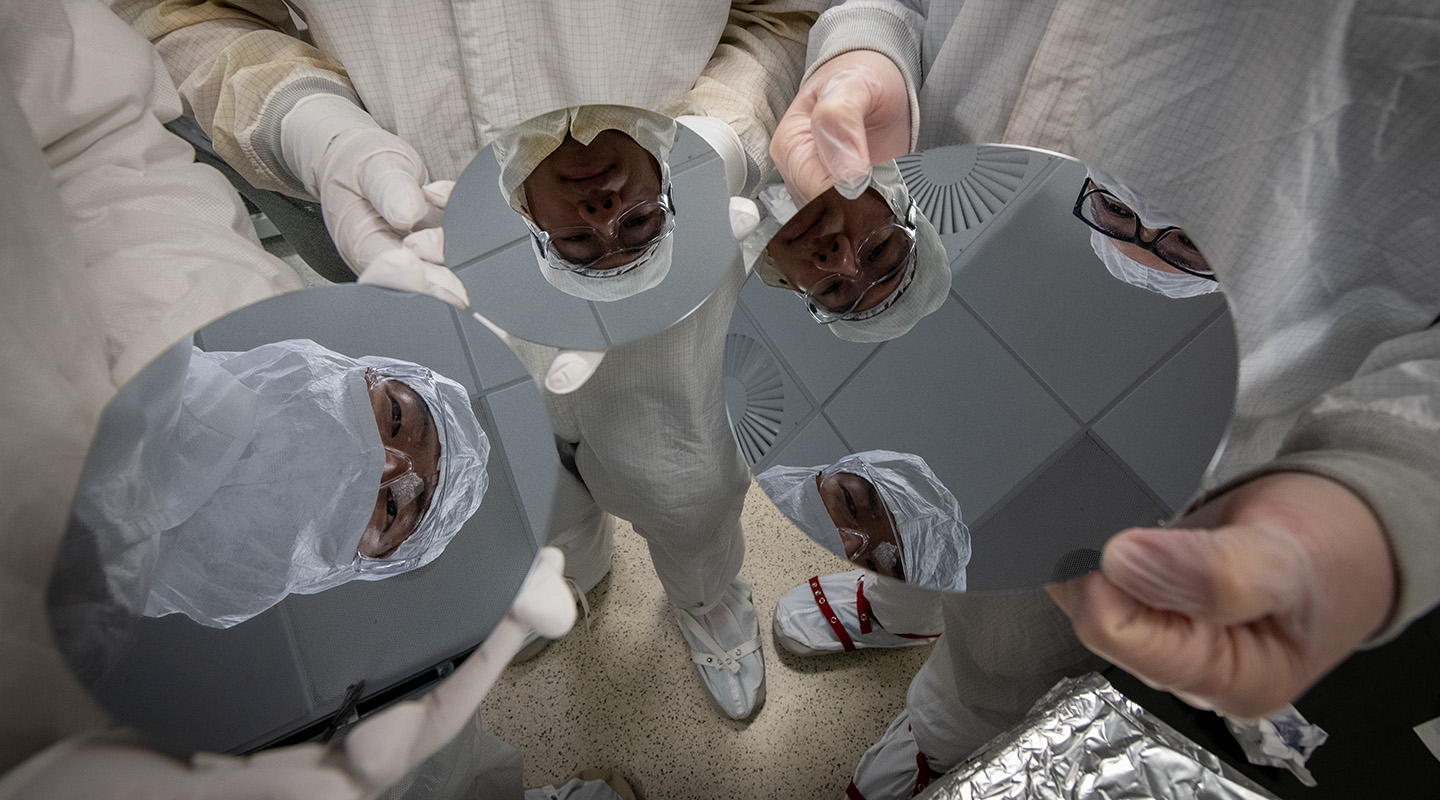

Led by senior author Irfan Siddiqi, a faculty scientist in Berkeley Lab's Applied Mathematics and Computational Research Division and senior advisor of QSA - the team fabricated aluminum-based superconducting devices with partially suspended superinductors on a 6-inch silicon wafer. The new approach allowed them to etch hundreds of sub-micron-sized superinductors in specific areas of the wafer, leaving most of the silicon surface un-etched and pristine. A low-temperature technique under vacuum removed the etching mask without damaging the fragile, suspended superinductors.

They found that this gentler cleaning process resulted in an 87% increase in inductance - or the flow of current needed to store data in a magnetic field - compared to conventional, non-suspended superinductors.

"It's a fabrication technique that could enable us to make super-inductances in both cleaner and more directed ways. It gives us a lot of flexibility to build devices," Santiago said.

In future work, Santiago, Siddiqi, and team aim to use the new technique to fabricate qubits as part of the 3D Integration project. (Siddiqi is also a professor of Electrical Engineering and Computer Science and heads the Physics Department at the University of California, Berkeley.)

"This pioneering approach could enable new pathways to the engineering and fabrication of superconducting qubits that are much less prone to noise, and more capable of handling complex computations and scientific problems central to ASCR's goals. Knowing how to make noise-resistant qubits will allow us to advance more efficient quantum computers directed at solving the scientific problems that are key to the Department of Energy's mission," said Bert de Jong, QSA director.

As Berkeley Lab joins the celebration of the International Year of Quantum Science and Technology, breakthroughs like this fabrication technique show the rapid progress in quantum technology, paving the way for more powerful and reliable quantum computers. To learn more about quantum R&D at Berkeley Lab, watch "Berkeley Lab Quantum: Advancing the Science and Technology of the Future."

This work was supported by the DOE Office of Science. Additional support was provided by the U.S. Army Research Office.