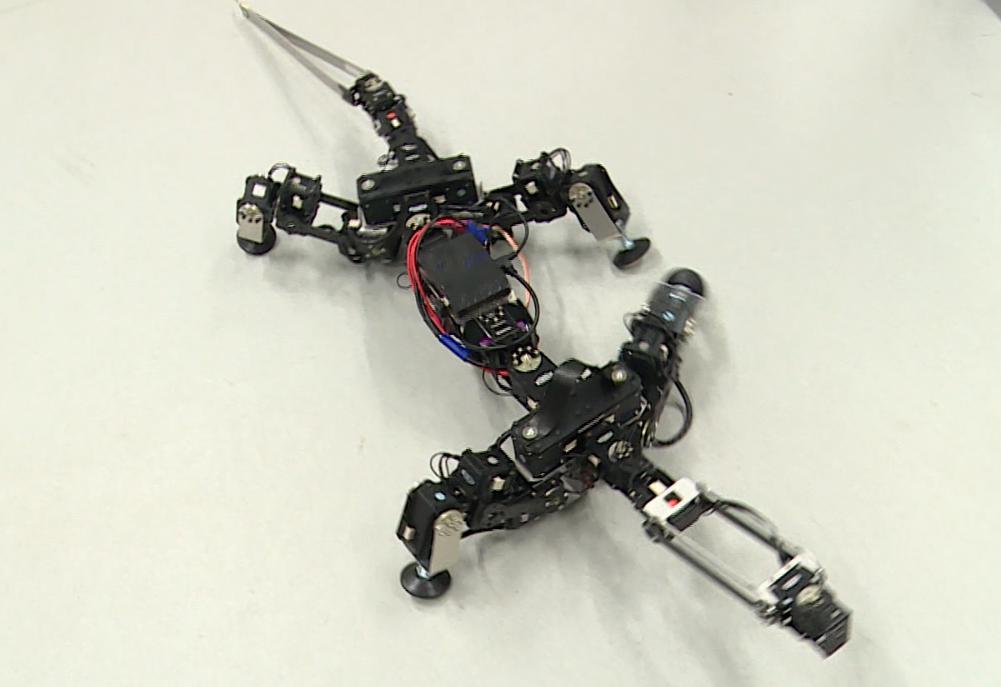

Krock robot resting on the grass © Tomislav Horvat and Kamilo Melo CC BY-SA

When the BBC commissioned two reptilian robots from the EPFL BioRob lab for a documentary on the African wilderness in 2016, the researchers could not have predicted how testing the devices in uncontrolled environments would change their approach to robotic design.

Auke Ijspeert and his team in the BioRobotics Lab (BioRob) in the School of Engineering had operated their bio-informed robots in natural environments before, but this was more for demonstration purposes than for scientific rigor. Tests of robotic function were usually carried out in the lab, for example using x-ray videos to compare robotic movements with the animals that inspired their design.

But that changed in November 2015, when Ijspeert and his colleagues received a request from British Broadcasting Corporation (BBC) producers to create two lifelike robots: one designed to mimic a crocodile and the other, a monitor lizard. Both species are found along the banks of the Nile River in Uganda, and the BioRob's task was to design and fabricate, in under one month, camera-concealing robots that could unobtrusively integrate themselves into this environment to capture the reptiles' nesting behavior and interactions.

Engineering adaptations

It was a request that seemed straightforward enough, and the researchers were confident in their abilities due to past experience with sprawling-posture robots like the Pleurobot and Orobot. But they were met with a first challenge when it came to balancing form and function: the robots developed as part of the Krock platform - SpyCroc and SpyLizard -needed to blend in perfectly with real crocodiles and monitor lizards to film their interactions, so a higher percentage of their weight had to be allocated to cameras and hyper-realistic skin.

"Part of the design process required anticipating what might happen later, and simplifying the design as much as possible to make the robots easier to repair in the field, where access to specialized parts and equipment is limited," explains Kamilo Melo, a former BioRob postdoctoral researcher who now leads biorobotics company KM-RoBoTa. To achieve this, the researchers relied on low-cost components that would be easy to swap out or replace.

On the ground in Uganda, the field conditions themselves posed unexpected challenges. The 38-degree weather would cause temperatures inside the robots to rise as high as 80 degrees, resulting in them overheating and shutting down. This required the researchers to work quickly before the daily temperature climbed, and to find work-arounds like operating the robots in short bursts interspersed with periods of cooling. They had to streamline the robotic design as much as possible to minimize the number of connecting parts, as more joints meant more access points for sand, dust, and moisture. And what first appeared to be a strength of the Krock design - such as structural rigidity - turned out to be a liability, as the rough terrain would simply cause inflexible components to break.

The BioRob lab has recently published the lessons learned as an open-source research and methodology resource in Science Robotics. They hope that their experience, coupled with design specifications using commonly available and simple, yet robust components, will help other researchers replicate their platform for their own projects.

Building a better biorobot

Based on their experience in Africa, the researchers developed an improved version of the Krock platform, Krock-2, which is more robust, flexible, and waterproof. With less need for elaborate camouflaging elements like realistic latex skin, the upgraded robot has great potential for disaster response and rescue applications.

The experience has also inspired new research avenues in the BioRob lab. "A big topic that integrates pure robotics and neuroscience is developing tactile skin with sensors that can detect interaction forces with the environment," Ijspeert says. "In robotics in general, we are very good at a replicating proprioception, but we are very bad at replicating all the senses we have in the skin, such as heat and touch. This technology is still very challenging, and we are interested in integrating it into our salamander-like robots."

On the industrial side, Melo is using his experience with the Krock platform to explore robotic reliability at KM-RoBoTa. "From a user perspective, I think reliability is very important, and based on what we learned in the field, we are focusing more on how to ensure that robots do not fail, even if it's raining or under unpredictable conditions," he says.

But for both Ijspeert and Melo, the technical improvements to the Krock platform based on trial-by-fire in the field is a just bonus. They explain that they are more interested in using the experience in Uganda to improve bio-informed robots as scientific tools - for example, in robotic paleontology to understand the locomotion of extinct species like dinosaurs. Although bones and fossils can be used to create animations and study kinematics, to understand the dynamic movements of dinosaurs, a physical model must be constructed that is subject to the same physical laws as the animals from the past.

"Everything we have done to improve robotic performance in the field is very exciting, because it is useful for search-and-rescue and other applications. But in the BioRob lab, our main contribution is collaborating with researchers from neuroscience, biomechanics, and paleontology to use robots as a physical tool to address scientific questions," Ijspeert says.

"With our open-source contributions in this study, we hope to make such platforms more affordable, while remaining precise enough for scientific purposes."