Molten Salt Reactors (MSRs) are nuclear fission reactors in which either the fuel and/or the coolant is a molten salt. Molten salt is salt which liquifies at elevated temperatures and can store massive amounts of thermal energy at atmospheric pressure.

When used as fuel the molten salt is dissolved with fissile material. A fissile material is defined as one which is capable of fission (a reaction in which the nucleus of an atom splits into two to release energy). This happens after the nucleus is hit by either a high energy (fast) neutron or low energy (slow) neutron. Examples of fissile materials are uranium-235, plutonium-239 or uranium-233 that may be mixed with other fissionable material such as uranium-238.

Learn more about nuclear fission and energy.

Help decarbonize industry for net zero goals

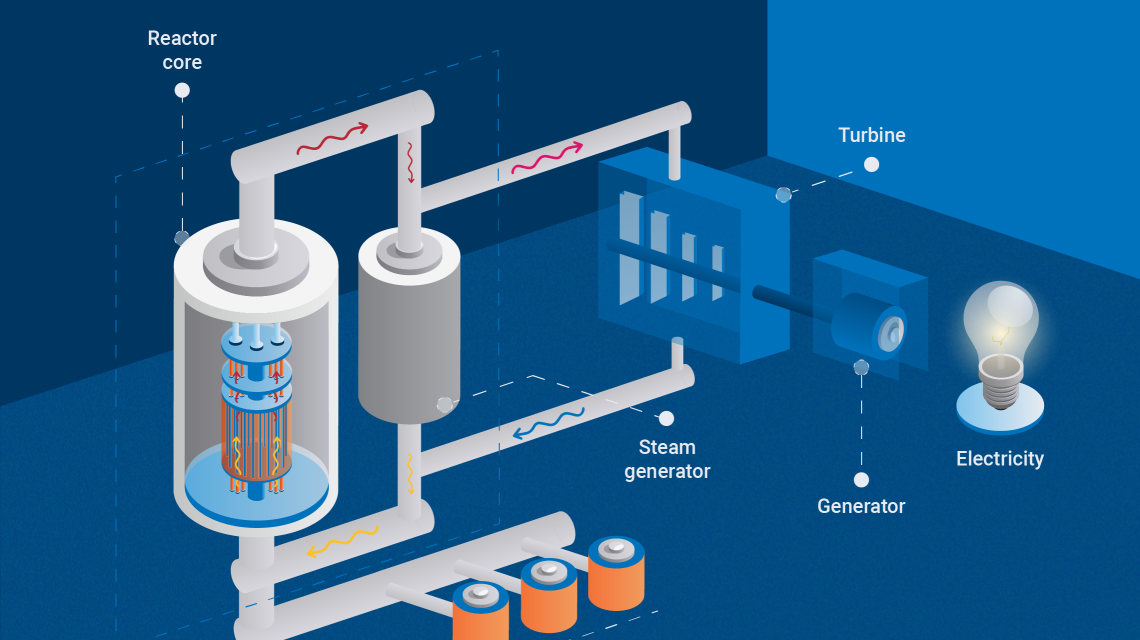

The majority of nuclear power plants around the world currently use pressurized water reactors (PWRs). In these, water is used as a coolant and is pumped under high pressure to the reactor core. There, the water is heated by the energy released by the fission of nuclei and released as steam, which drives turbines to produce electricity.

However, if salt is used as a primary coolant rather than water, it can absorb huge amounts of heat at atmospheric pressure, enabling reactors using this technology to operate at very high temperatures. This could in turn enable the production of high-grade heat, opening up the possibility of decarbonizing industrial processes such as producing hydrogen for green steel without the large amounts of greenhouse gases (GHG) currently emitted when producing hydrogen with fossil fuels.

International interest is increasing in MSRs , because they have the potential to provide large amounts of efficient and cost effective electricity and produce high-temperature process heat usable for various industrial applications. The same advantages of high-temperature gas-cooled reactors (which use helium gas as a coolant instead of molten salt).

Find out how nuclear can replace coal as part of the clean energy transition.

Small high-level nuclear waste footprint

Initially developed in the 1950s, some more recent designs of MSRs do not require solid fuel, which eliminates the need for manufacturing and disposing of it. The MSRs with liquid fuel technology generate less high-level nuclear waste because they have a higher burn up limit in the fuel used to power them, resulting in less waste.

Passive safety features

In addition, MSRs in general have passive safety features - design elements that enhance safety through natural physical principles without requiring human intervention. For example, if a reactor in an MSR overheats, the liquid salt expands and naturally increases the leakage of neutrons from the reactor core, meaning they are no longer available to cause fission. This reduces the nuclear fission rate and the temperature. Some MSRs feature a special drain tank located below the reactor. If the reactor gets too hot, a plug made of solid salt melts, allowing the molten salt to flow into the drain tank, stopping the reaction completely without any need for human intervention or external power.

Sustainable fuel cycle options

Uranium, plutonium and thorium can all be dissolved in appropriate salt compositions, meaning that MSRs can potentially adapt to a variety of nuclear fuel cycles (such as uranium-plutonium and thorium-uranium cycles), enabling more sustainable fuel cycles. Using plutonium more effectively would eliminate most of the waste generated in current light water reactors using this fuel. In addition, thorium is three times more abundant than uranium, and easier to mine.

You can find out more in our explainer on uranium.

How would MSRs produce low-carbon energy?

MSRs in development today are based on two main designs. The first design uses traditional solid fuel rods, with molten salts used as a coolant instead of water. The second design is a liquid fuel model, in which fissile material (uranium or thorium) is dissolved into a molten salt-based coolant. In these liquid fuel designs, the fission products are dissolved into the molten salt, which is able to circulate through the reactor core where it undergoes fission and generates heat. The heat is then transferred to a secondary loop, where it drives a turbine to produce electricity. A variation of these designs, where a molten-fuel salt is loaded into sealed metallic tubes, and a secondary salt is used as coolant, is also under development.

How close are MSR designs to commercial deployment?

Several MSR designs are currently under development. While many new designs follow similar principles to the reactors developed in the Molten Salt Reactor Experiment at the US Oak Ridge National Laboratory in the 1960s, such as the salt "freeze plug", there are also many new ideas to be researched, developed and proven. These include different fuel cycles, different fuel salts and modular designs - which would make it possible for systems and components to be factory-assembled and transported as a unit to a location for installation.

In Canada, a molten salt-based small modular reactor (SMR) concept passed a crucial pre-licensing vendor design review in 2023, the first such review completed for an MSR. Other projects, including in China, Russia and the US, continue to make progress, with the hope that MSRs could begin to see deployment as soon as the mid-2030s.