Inside a UC Davis engineering lab, tiny round pellets swirl in a brown liquid inside a 5-liter glass tank. The tank, a bioreactor, is brewing edible fungi high in protein and designed to look and taste like meat.

In another lab on campus, a liquid nitrogen tank nicknamed "cryocow" holds frozen vials of cow muscle stem cells. Scientists hope to one day turn these cells into lab-grown meat, creating the burgers of the future.

Researchers with the Integrative Center for Alternative Meat and Protein, or iCAMP, at UC Davis are leading projects like these to meet the world's growing demand for meat in environmentally sustainable ways. Their goal is to identify alternative proteins that can be brought to market on a large scale. These proteins could come from fungi, plants, cultivated meat, or even innovative hybrids that combine conventional meat with alternative proteins.

The world's demand for meat is expected to increase by at least 25%, and as much as 100%, by 2050, driven by a rising global population and an increasing appetite for meat in developing countries.

"Meeting that demand is not likely to happen just by growing more animals," said David Block, director of iCAMP.

Producing meat also contributes significantly to global greenhouse gas emissions. But for alternative proteins to be widely accepted by consumers, scientists and marketers need to overcome significant challenges.

UC Davis is well positioned to provide the technology and knowledge needed to advance alternative proteins because of its interdisciplinary teams of researchers from the animal and food sciences, biological sciences, agricultural and chemical engineering and sensory sciences.

iCAMP brings those researchers together with industry experts and food innovators.

Mycofood: fungi of the future

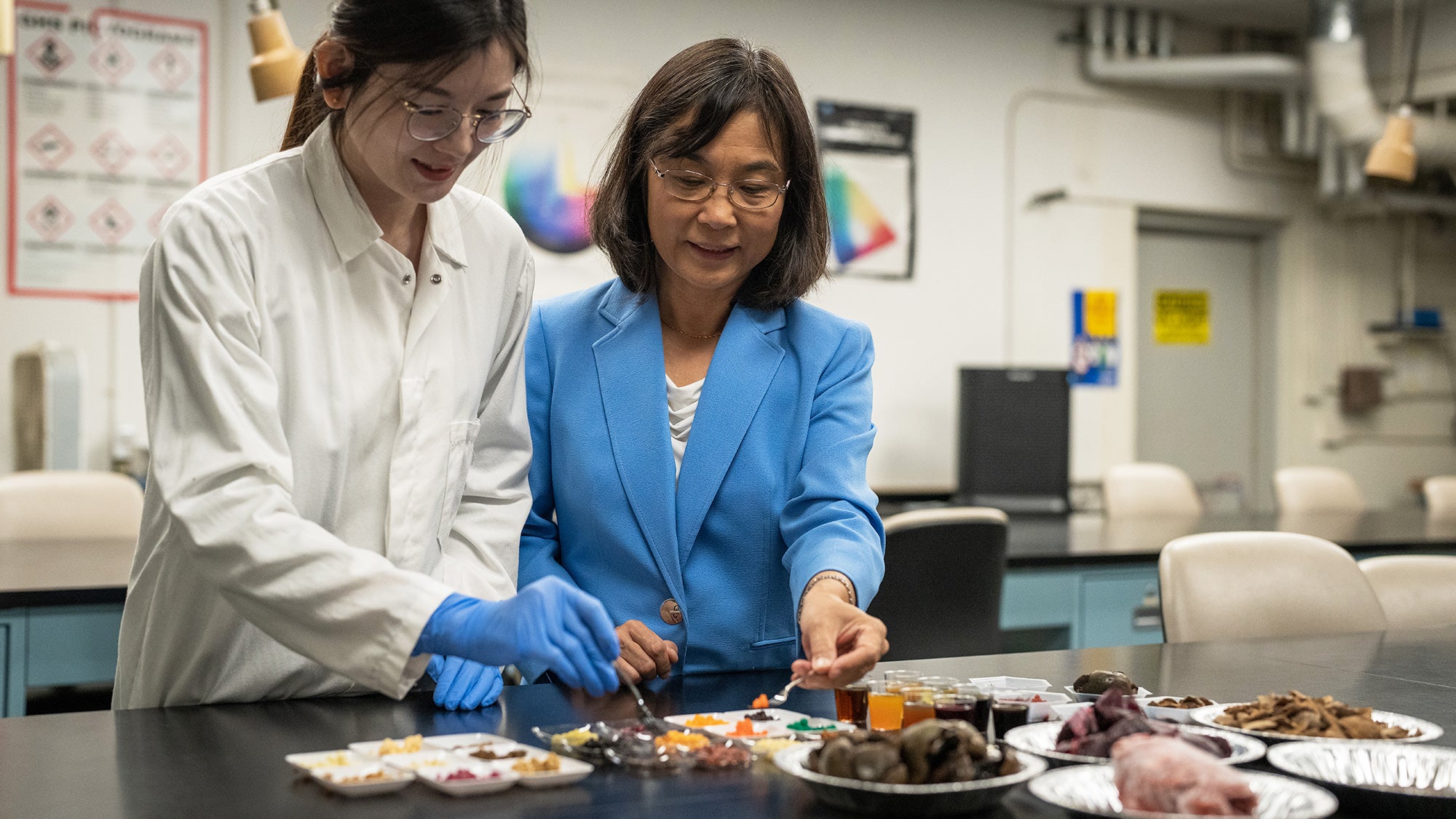

Professor Ruihong Zhang in the Department of Biological and Agricultural Engineering is brewing the next generation of mycofood - food made from fungi in bioreactors.

She's creating high-protein pellets from mycelium, the thread-like, branching parts of fungi. The fungi take on the color, flavor and nutrients of whatever they're fed in the bioreactor. Zhang has fed them almond and walnut hulls, pistachio shells, carrots, tomatoes, red beets and even the byproducts of cheese-making.

"The fungi pellets will absorb bioactive compounds like antioxidants from almond hulls as well as the brown color," Zhang said. "If fed tomato pomace, they'll have a reddish brown color."

The pellets can be transformed into all sorts of food. Zhang first used them to replace the tapioca balls in boba tea. She's also made jerky from them. Dried pellets can also be ground into a powder to mix in other foods.

Zhang said she believes mycofoods, especially those made with agricultural byproducts like almond hulls, are more sustainable than animal or plant proteins.

"They're a low cost, highly nutritious source of protein with a low carbon footprint," Zhang said.

Her team's work led to a startup company that's now making fungal-based caviar, modeled after sturgeon roe. Optimized Foods uses the mycelium pellets to provide the structure of the roe and cultivated caviar, grown in a lab using sturgeon stem cells.

Mycoproteins and hybrid food

Making mycoproteins more widely available is the next step for companies already producing food from fungi. The Better Meat Co. of West Sacramento makes a mycelium protein called Rhiza. The company sells dehydrated white cubes of Rhiza to food producers to blend in plant-based foods or animal meat. Rhiza can also be eaten on its own.

"We know it's not going to be possible to make everyone stop eating meat," said Doni Curkendall, Better Meat's executive vice president of business operations. "But we think you can make a small change, and for us, that means creating hybrid products."

Hybrid products are growing in popularity, appealing to flexitarians, or part-time vegetarians. Research shows most people who eat plant-based meat alternatives also eat animal meat.

Rhiza mycoprotein is made by feeding fungi starchy foods through fermentation. This produces long fibers of mycelium, which are then drained or dehydrated, creating a product that has a meat-like structure and chewiness.

Currently, Better Meat produces Rhiza in a pilot plant. Curkendall hopes UC Davis' iCAMP can help them scale up to commercial production.

"UC Davis has the expertise," she said. "They have the facilities and people that can help us continue to do our research and continue to grow in this space."

Curkendall envisions a time when Sacramento - known for being the farm-to-fork capital of California - will also be known as the fermentor-to-fork capital.

Meat grown in a lab

Cultivated meat, or meat grown in a lab using animal stem cells, is the latest alternative protein. The U.S. Department of Agriculture approved its sale nationally in 2023, but it may not be available in grocery stores for years.

"We see cows grazing on grass and turning it into high-quality protein - meat," said Anna Denicol, associate professor in the Department of Animal Science at UC Davis. "In the lab, we're trying to replicate something that nature took thousands of years to perfect."

Denicol is one of two UC Davis professors developing cow stem cells lines for cultivated beef. To make cultivated meat, cow stem cells are fed the right nutrients to help them grow and multiply. The cells also must differentiate into muscle cells, fat cells and connective tissue needed to make meat.

Scientists can use adult cow stem cells, but the problem with these cells is that they don't duplicate forever, said Lucas Smith, assistant professor in the UC Davis Department of Neurobiology, Physiology and Behavior.

"The challenge is to expand them to greater degrees than you typically would in the body and then have them efficiently create muscle in a different environment," Smith said.

Researchers can also use embryonic stem cells, which can replicate indefinitely in the right conditions. However, getting these cells to become the muscle, fat and connective tissue is much harder and takes longer.

The cultivated meat industry uses expensive, complex ingredients to keep cells alive, in a process borrowed from the biopharmaceutical industry. But food needs to be produced much more cheaply than pharmaceuticals. Also, the cells would need to grow in 250,000-liter fermentation tanks.

"The reality is that no one in the world has ever grown animal cells using more than a 25,000-liter fermentation tank. It's still an open question whether it will work," said Block, who is also a professor in the departments of chemical engineering and viticulture and enology.

UC Davis researchers, along with iCAMP and industry partners, are hoping to meet this challenge. Block said he remains hopeful that technological innovations could lead to widespread commercialization of cultivated meat.

"It's probably 10 to 15 years away from being in all the supermarkets all across the country, but I am very optimistic that we'll get there."

Making meat substitutes taste like meat

Even with all the research and new technology, people might still be hesitant to buy alternative proteins. One big reason is the cost. Even the plant-based proteins on the market now are often more expensive than products made from cows, pigs or chickens.

Another challenge is making these alternatives have the taste, texture and mouthfeel of real meat. Soy and pea, the main ingredients in many plant-based proteins, can have off flavors that need to be masked, Block noted. They also need fat to give them the right mouthfeel and flavor.

But Block said part of the research mission of iCAMP is to determine what's critical for consumers to buy these products.

"There is no projection that we're going to need less meat," Block said. "I would expect conventional animal agriculture may stay the same or even grow but these other methods of producing meat need to fill that supply gap."